Catalyst Changes, Downstream Improvements Increase FCC Propylene Yields

SUMMARY

Increasing propylene yields from an FCC can be an attractive alternative to a steam cracker. Reactor and catalyst system changes can lead to much higher propylene yields than conventional FCC operations. Increasing propylene yields place additional demands on the gas plant, which need to be evaluated as part of the decision-making process. Otherwise valuable C4- products could be lost to fuel gas.

TEXT

Higher propylene yields from FCC units require higher reactor temperature and changes in the catalyst system. It is important that the plant operator concurrently evaluate reactor yields, wet-gas compressor, and gas-plant performance to determine the most cost-effective revamp strategy.

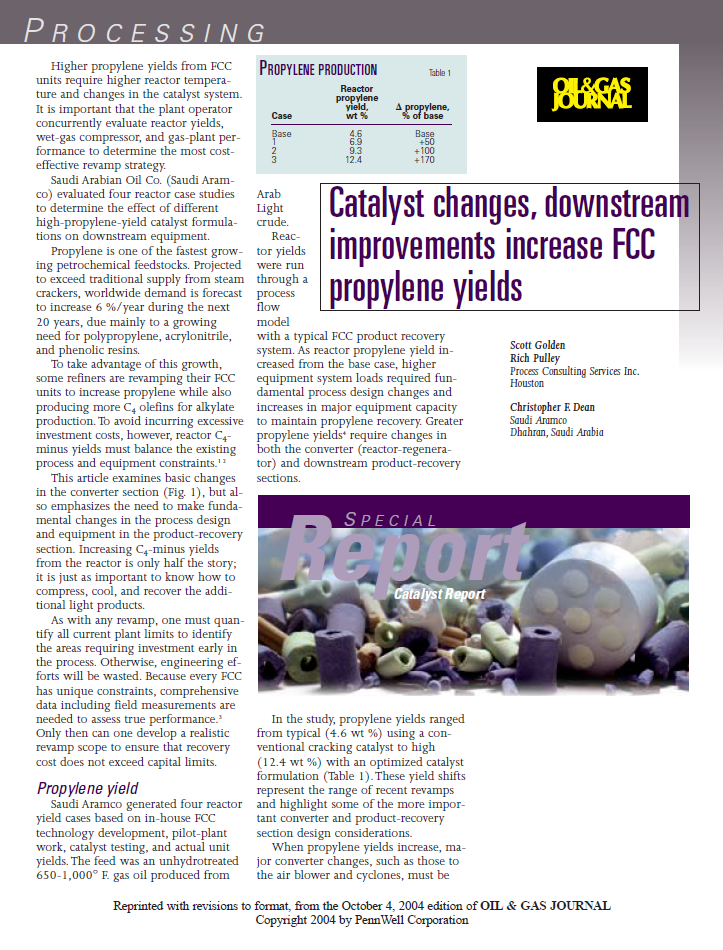

Saudi Arabian Oil Co. (Saudi Aramco) evaluated four reactor case studies to determine the effect of a different high-propylene-yield catalyst formulations on downstream equipment.

Propylene is one of the fastest growing petrochemical feedstocks. Projected to exceed traditional supply from steam crackers, worldwide demand is forecast to increase 6%/year during the next 20 years, due mainly to a growing need for polypropylene, acrylonitrile, and phenolic resins…