Refiners Must Optimize FCC Feed Hydrotreating When Producing Low-sulfur Gasoline

SUMMARY

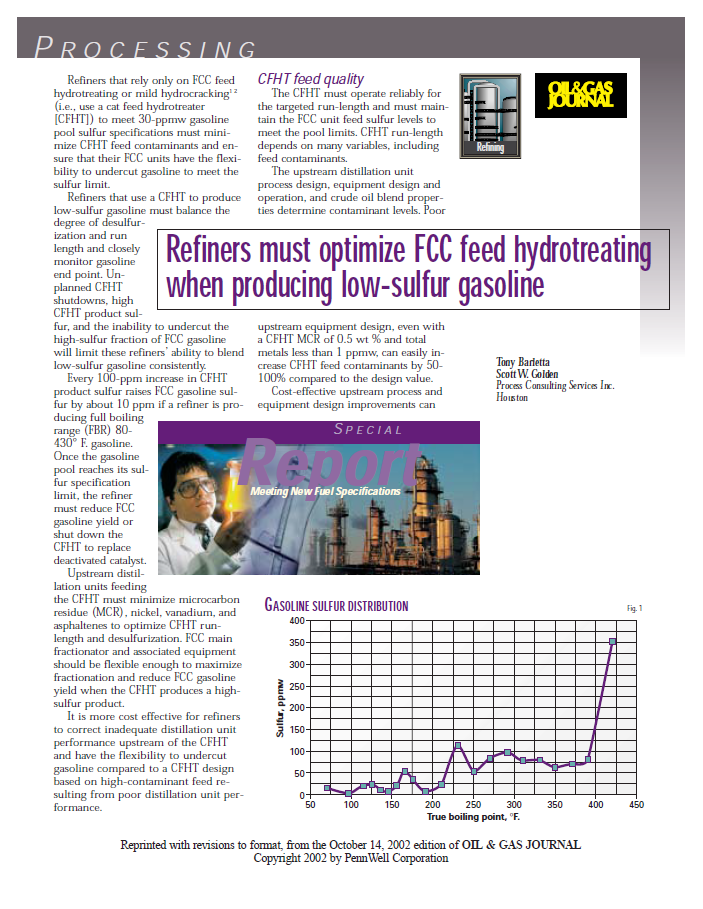

Meeting lower gasoline product sulfur levels requires understanding sulfur distribution and species as function of the FCC gasoline boiling range. Gasoline pool sulfur limits can be achieved by minimizing contaminants in the cat feed hydrotreater (CFHT) feed and improving fractionation between gasoline and LCO. In many cases these options are much less expensive than designing the CFHT based on high-contaminant feed resulting from poor distillation unit performance.

TEXT

Refiners that rely only on FCC feed hydrotreating or mild hydrocracking (i.e., use a cat feed hydrotreater [CFHT]) to meet 30-ppmw gasoline pool sulfur specifications must minimize CFHT feed contaminants and ensure that their FCC units have the flexibility to undercut gasoline to meet the sulfur limit.

Refiners that use a CFHT to produce low-sulfur gasoline must balance the degree of desulfurization and run length and closely monitor end point. Unplanned CFHT shutdowns, high CFHT product sulfur, and the inability to undercut the high-sulfur fraction of FCC gasoline will limi these refiners' abilit to blend low-sulfur gasoline consistently.

Every 100-ppm increase in the CFHT product sulfur raises FCC gasoline sulfur by about 10 ppm if a refiner is producing full boiling range (FBR) 80-430⁰F. gasoline. Once the gasoline pool reaches it sulfur specification limit, the refiner must reduce FCC gasoline yield or shut down the CFHT...