Consider Retrofits to Handle High-Viscosity Crudes

SUMMARY

Refiners must fine-tune crude unit process design and energy balance to process a heavy feedslate.

TEXT

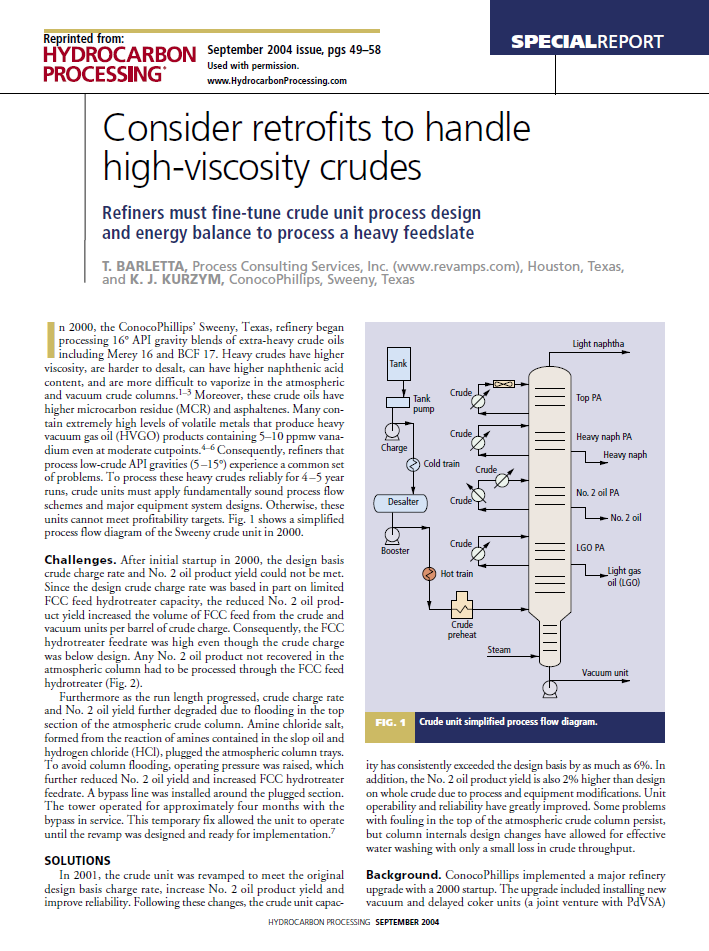

In 2000, the ConocoPhillips’ Sweeny, Texas, refinery began processing 16° API gravity blends of extra-heavy crude oils including Merey 16 and BCF 17. Heavy crudes have higher viscosity, are harder to desalt, can have higher naphthenic acid content, and are more difficult to vaporize in the atmospheric and vacuum crude columns. Moreover, these crude oils have higher microcarbon residue (MCR) and asphaltenes. Many contain extremely high levels of volatile metals that produce heavy vacuum gas oil (HVGO) products containing 5–10 ppmw vanadium even at moderate cutpoints. Consequently, refiners that process low-crude API gravities (5 –15°) experience a common set of problems. To process these heavy crudes reliably for 4 – 5 year runs, crude units must apply fundamentally sound process flow schemes and major equipment system designs. Otherwise, these units cannot meet profitability targets. Fig. 1 shows a simplified process flow diagram of the Sweeny crude unit in 2000.

After initial startup in 2000, the design basis crude charge rate and No. 2 oil product yield could not be met. Since the design crude charge rate was based in part on limited FCC feed hydrotreater capacity, the reduced No. 2 oil product yield increased the volume of FCC feed from the crude and vacuum units per barrel of crude charge. Consequently, the FCC hydrotreater feedrate was high even though the crude charge was below design. Any No. 2 oil product not recovered in the atmospheric column had to be processed through the FCC feed hydrotreater (Fig. 2).

Furthermore as the run length progressed, crude charge rate and No. 2 oil yield further degraded due to flooding in the top section of the atmospheric crude column. Amine chloride salt, formed from the reaction of amines contained in the slop oil and hydrogen chloride (HCl), plugged the atmospheric column trays...