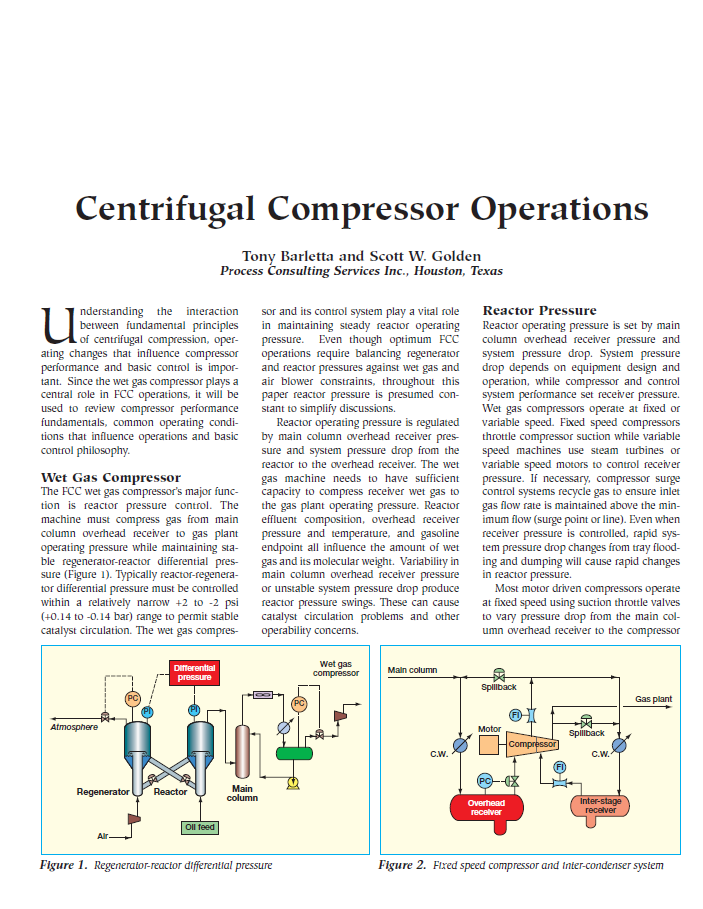

The wet gas compressor is used as an example in this article reviewing compressor performance, operating conditions and basic control philosophy - an aid to understanding the interactions influencing compressor performance and control.

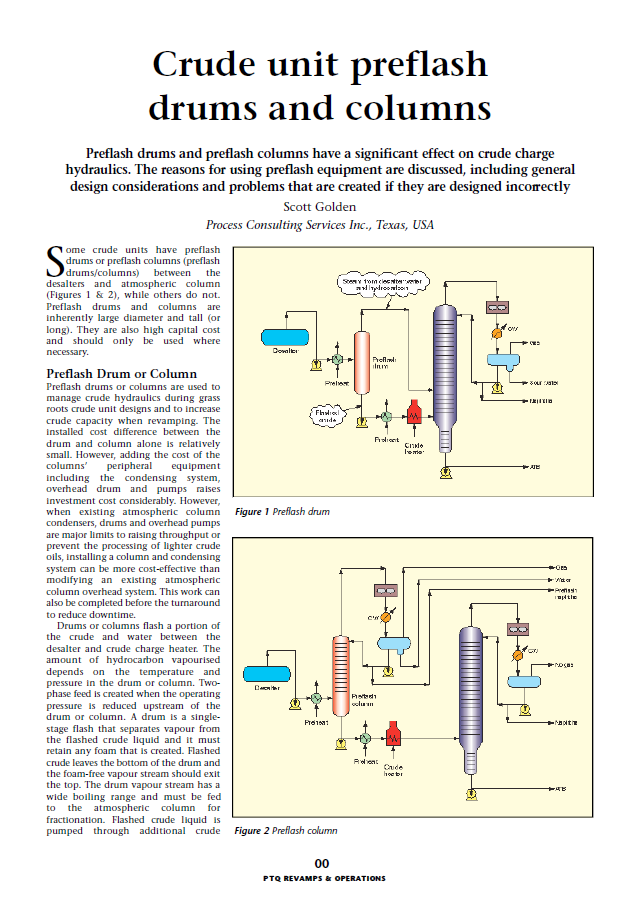

Read MorePreflash drums and preflash columns have significant effect on crude charge hydraulics. The reason for using preflash equipment are discussed, including general design considerations and problems that are created if they are designed incorrectly.

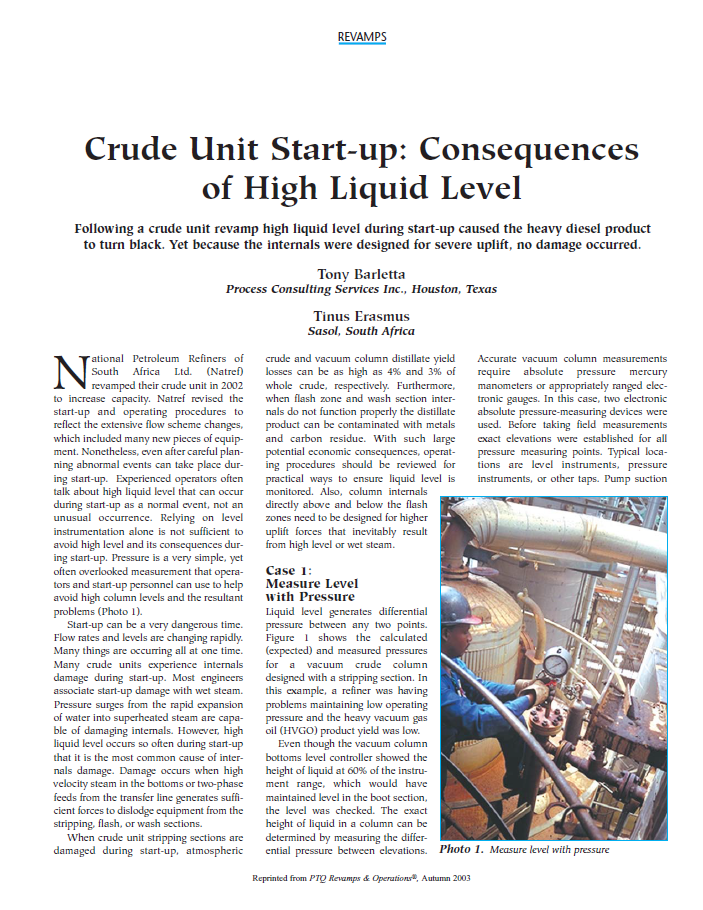

Read MoreFollowing a crude unit revamp high liquid level during start-up caused the heavy diesel product to turn black. Yet because the internals were designed for severe uplift, no damage occurred.

Read MoreWorld heavy crude volumes are increasing, and as a result CDU/VDU operating problems and the frequency of unscheduled outages is also increasing. Conventional CDU/VDU designs will not operate reliably or profitably on the more challenging crudes. This article addresses problem areas and identifies specific sections requiring investment to maintain profitability throughout a 4-5 year run length for refiners processing heavy crudes.

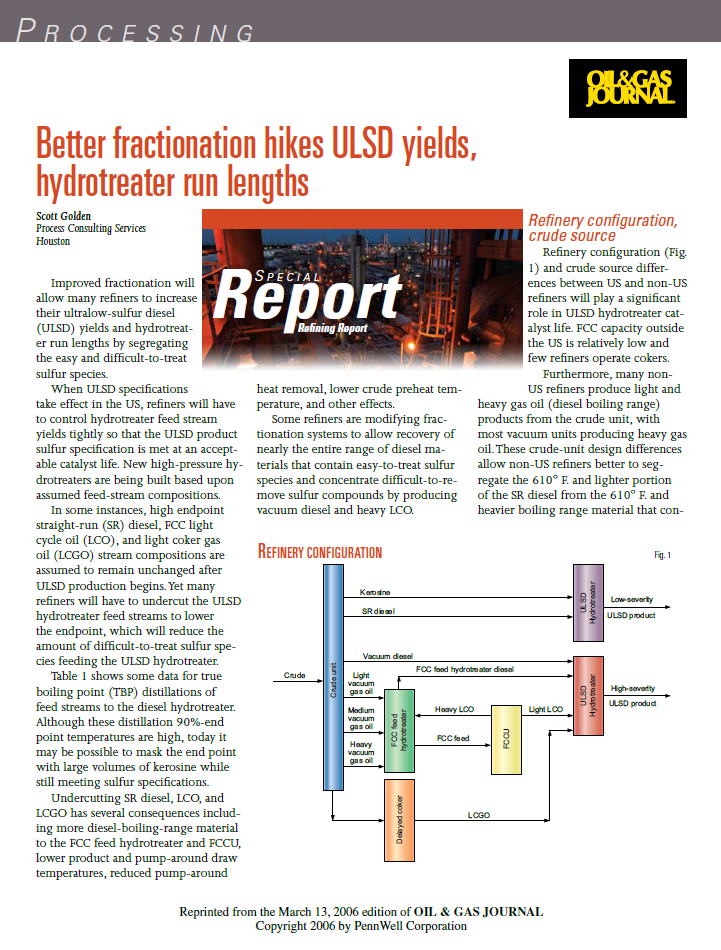

Read MoreImproved CDU, FCC and Coker main column fractionation maximizes diesel boiling range yields while eliminating hard-to-treat sulfur components from the hydrotreater feed. Hydrotreater run lengths can be materially improved by improving the segregation of easy-to-treat and hard-to-treat sulfur species in upstream distillation units.

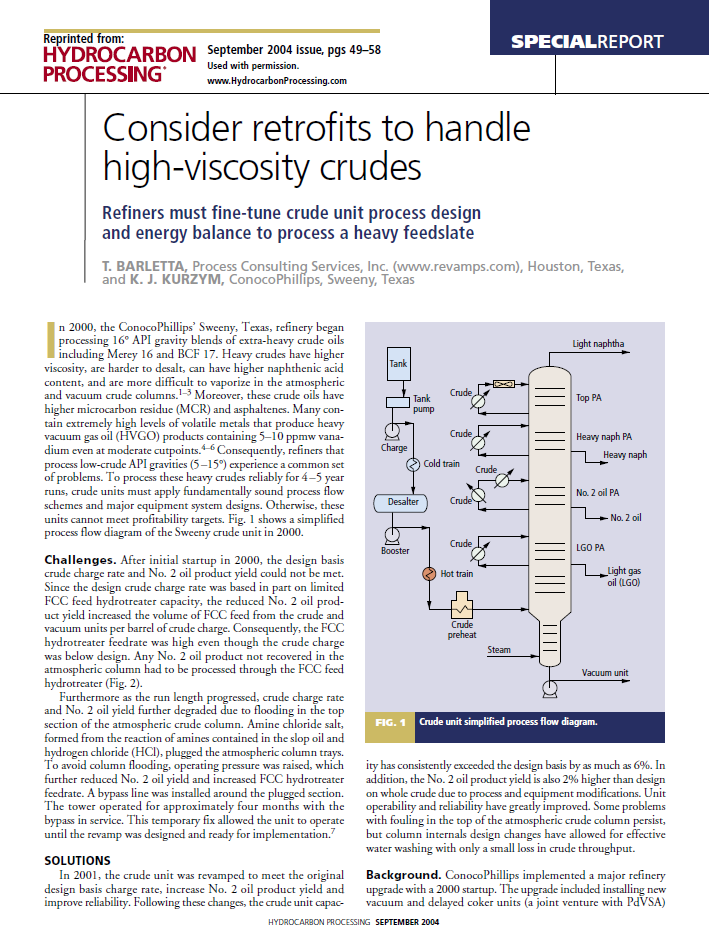

Read MoreRefiners must fine-tune crude unit process design and energy balance to process a heavy feedslate.

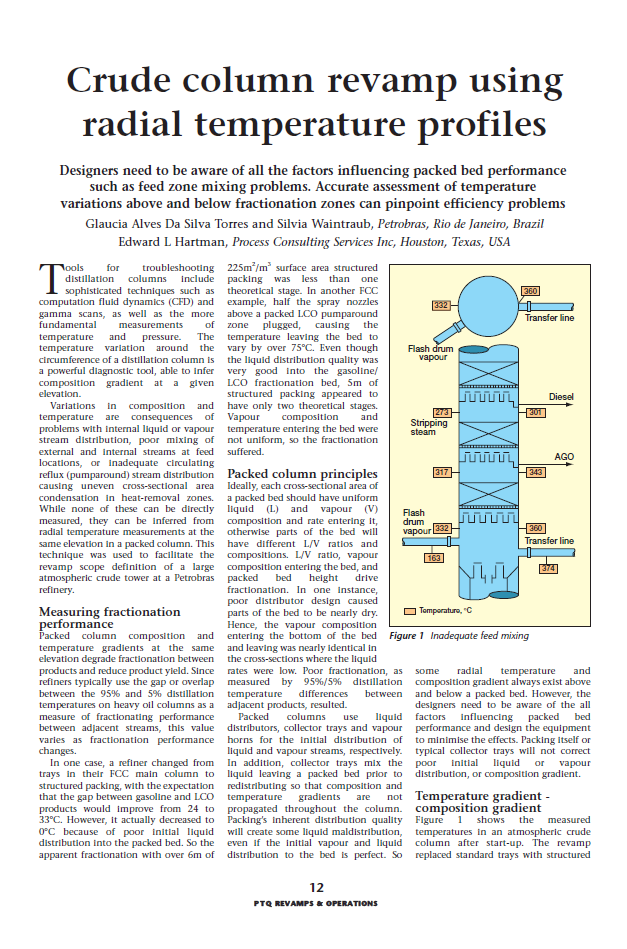

Read MoreDesigners need to be aware of all the factors influencing packed bed performance such as feed zone mixing problems. Accurate assessment of temperature variations above and below fractionation zones can pinpoint efficiency problems.

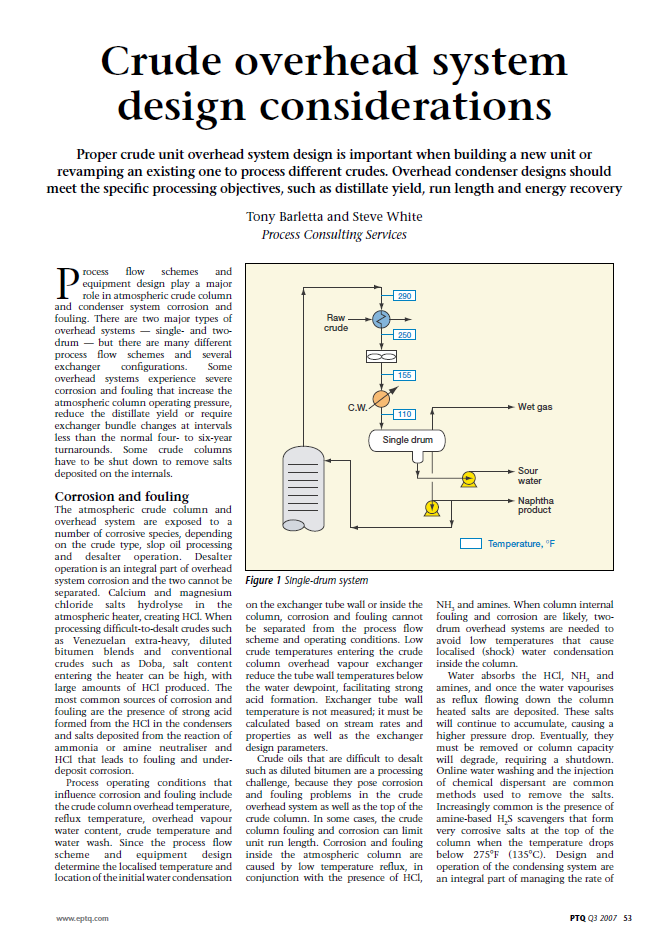

Read MoreProper crude unit overhead system is important when building a new unit or revamping an existing one to process different crudes. Overhead condenser designs should meet the specific processing objectives, such as distillate yield, run length and energy recovery.

Read MoreAn account of a crude vacuum unit revamp in which detailed calculation of the true performance of existing equipment, plus a realistic calculation of the benefits a revamp would bring, raised diesel production by 14.5 vol% on crude.

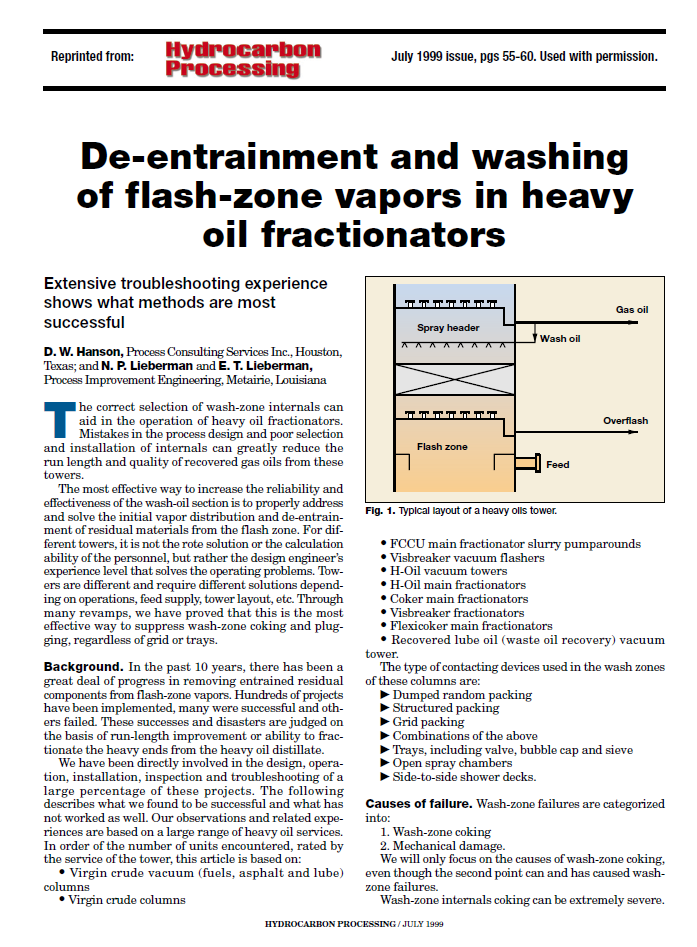

Read MoreExtensive troubleshooting experience shows what methods are most successful.

Read MoreHeavy Canadian crudes pose serious challenges during the process of desalting due to their inherent properties. This article presents an overview of critical desalter design and operating considerations to overcome various operational issues.

Read MorePreheat train design for heavy Canadian crudes can be very challenging, requiring an approach not normally required with other crudes.

Read MoreNew units for processing heavy crudes should not be designed using conventional practices or run length with be short, and product yields and quality poor.

Read MoreUsing field pressure data, a refiner made a low-capital modification on a crude distillation column to increase throughput without a shutdown.

Read MoreFundamental design considerations influencing diesel and vacuum gas oil (VGO) recovery when revamping existing or designing grassroots crude units.

Read MoreInstallation of vortex tube clusters in crude unit preflash drums has eliminated foam carry-over, increasing diesel and atmospheric gasoil product yields. By avoiding preflash drum replacement, these retrofits have cut revamp investment.

Read MoreCost-effective exchanger network solutions, designed to increase crude preheat temperature and reduce energy consumption, need to rely on more than just pinch technology if they are to be successful.

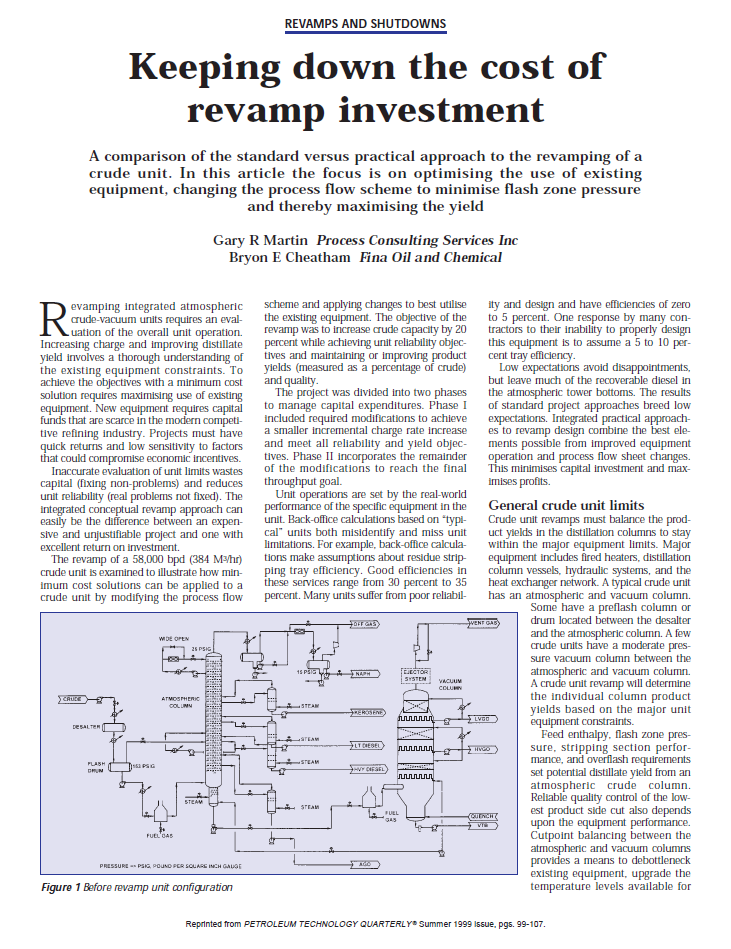

Read MoreA comparison of the standard versus practical approach to the revamping of a crude unit. In this article the focus is on optimising the use of existing equipment, changing the process flow scheme to minimise flash zone pressure and thereby maximising the yield.

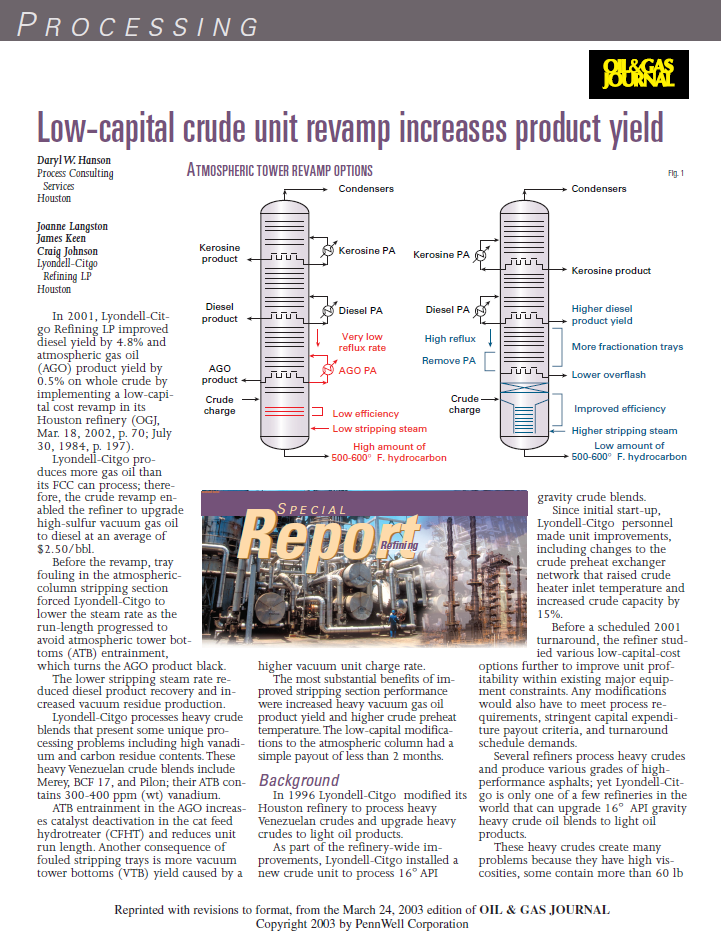

Read MoreCrude unit revamps can sometimes yield large economic improvements with low-capital investment. In this case study, improving atmospheric crude column stripping section efficiency improved diesel yields and unloaded the downstream vacuum column ejectors, increasing VGO yield. The low-capital modifications made in this revamp had a simple payout of less than 2 months.

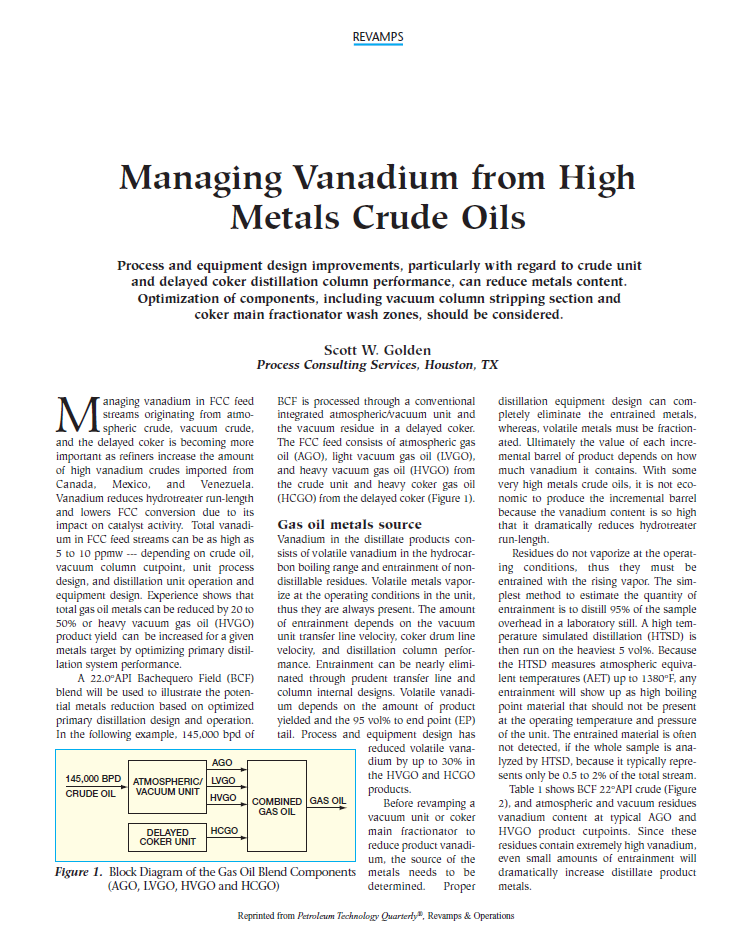

Read MoreProcess and equipment design improvements, particularly with regard to crude unit and delayed coker distillation column performance, can reduce metals content. Optimization of components, including vacuum column stripping section and coker main fractionator wash zones, should be considered.

Read More