Crude Unit Revamp Increases Diesel Yield

SUMMARY

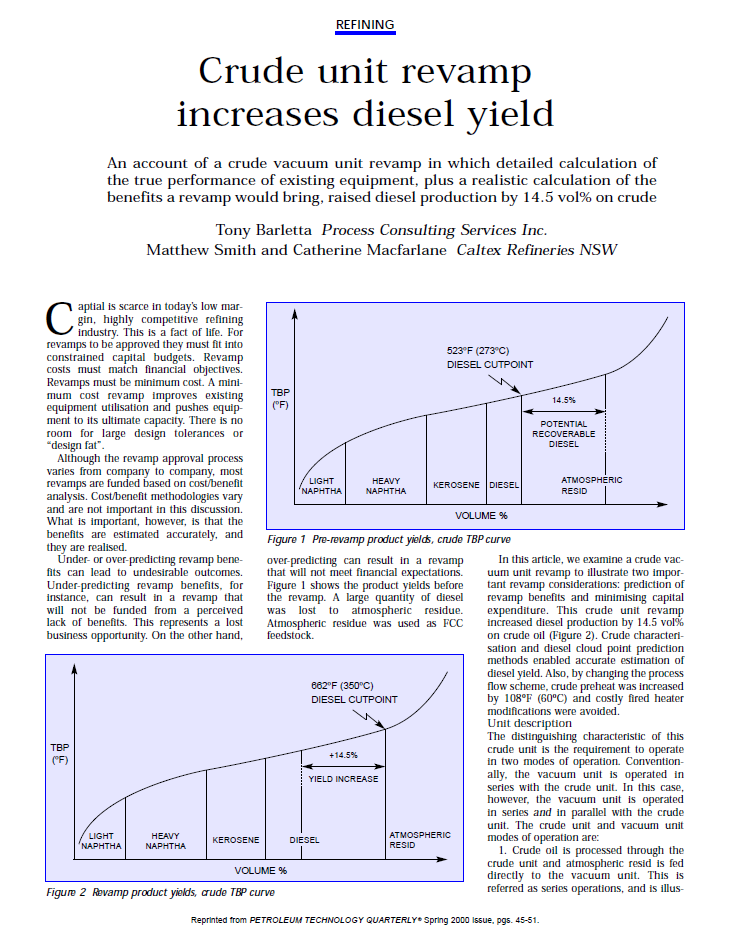

An account of a crude vacuum unit revamp in which detailed calculation of the true performance of existing equipment, plus a realistic calculation of the benefits a revamp would bring, raised diesel production by 14.5 vol% on crude.

TEXT

Captial is scarce in today’s low margin, highly competitive refining industry. This is a fact of life. For revamps to be approved they must fit into constrained capital budgets. Revamp costs must match financial objectives. Revamps must be minimum cost. A minimum cost revamp improves existing equipment utilisation and pushes equipment to its ultimate capacity. There is no room for large design tolerances or “design fat”.

Although the revamp approval process varies from company to company, most revamps are funded based on cost/benefit analysis. Cost/benefit methodologies vary and are not important in this discussion. What is important, however, is that the benefits are estimated accurately, and they are realised.

Under- or over-predicting revamp benefits can lead to undesirable outcomes. Under-predicting revamp benefits, for instance, can result in a revamp that will not be funded from a perceived lack of benefits...