Foam Control in Crude Units

SUMMARY

Installation of vortex tube clusters in crude unit preflash drums has eliminated foam carry-over, increasing diesel and atmospheric gasoil product yields. By avoiding preflash drum replacement, these retrofits have cut revamp investment.

TEXT

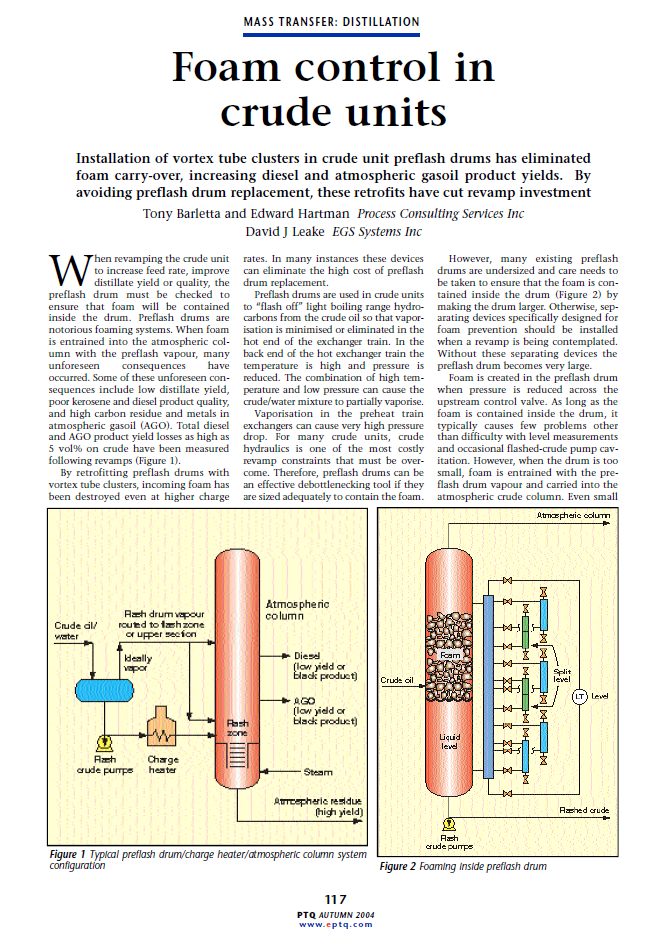

When revamping the crude unit to increase feed rate, improve distillate yield or quality, the preflash drum must be checked to ensure that foam will be contained inside the drum. Preflash drums are notorious foaming systems. When foam in entrained into the atmospheric column with the preflash vapour, many unforeseen consequences have occurred. Some of these unforeseen consequences include low distillate yield, poor kerosene and diesel product quality, and high carbon residue and metals in atmospheric gasoil (AGO). Total diesel and AGO product yield losses as high as 5 vol% on crude have been measured following revamps.

By retrofitting preflash drums with vortex tube clusters, incoming foam has been destroyed even at higher charge rates. In many instances these devices can eliminate the high cost of preflash drum replacement.

Preflash drums are used in crude units to "flash off" light boiling range hydrocarbons from the crude oil so that vaporization is minimised or eliminated in the hot end of the exchanger train. In the back end of the hot exchanger train...