Maximising Diesel Recovery From Crude

SUMMARY

The CDU/VDU process flow scheme is reviewed, including equipment design and operating fundamentals used to maximise straight-run diesel recovery. Factors important to increasing diesel yield are discussed in detail.

TEXT

Increased recovery of straight-run (SR) diesel from crude oil improves refinery profitability. Low crude/vacuum unit (CDU/VDU) SR diesel recovery is caused by existing unit process flow schemes, equipment designs and operating conditions. Since many FCC or hydrocracker feeds contain 25–35% or more diesel boiling-range material, there is significant opportunity to improve recovery. Low or moderate capital investments have increased refinery ULSD product yields by more than 5% on whole crude.

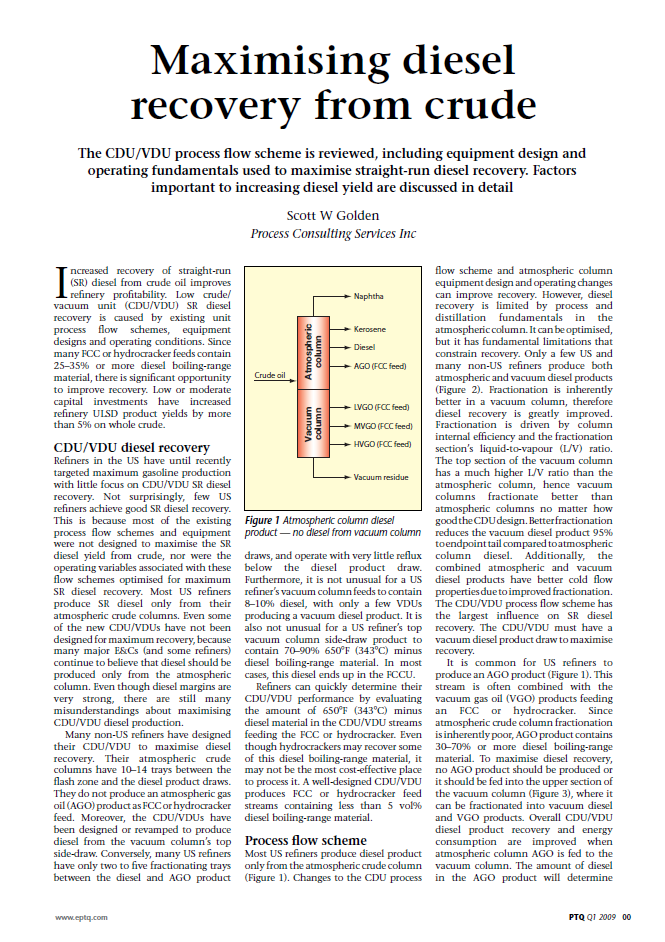

Refiners in the US have until recently targeted maximum gasoline production with little focus on CDU/VDU SR diesel recovery. Not surprisingly, few US refiners achieve good SR diesel recovery. This is because most of the existing process flow schemes and equipment were not designed to maximise the SR diesel yield from crude, nor were the operating variables associated with these flow schemes optimised for maximum SR diesel recovery. Most US refiners produce SR diesel only from their atmospheric crude columns. Even some of the new CDU/VDUs have not been designed for maximum recovery, because many major E&Cs (and some refiners) continue to believe that diesel should be produced only from the atmospheric column. Even though diesel margins are very strong, there are still many misunderstandings about maximising CDU/VDU diesel production.

Many non-US refiners have designed their CDU/VDU to maximise diesel recovery. Their atmospheric crude columns have 10–14 trays between the flash zone and…