Understanding Centrifugal Compressor Performance

SUMMARY

Understanding how FCC and Delayed Coker wet gas compressor capacity is impacted by system pressure drop allows low cost changes to be made without expensive compressor modifications. In many instances high pressure drop caused by poor system design reduces unit capacity, lowers conversion, or raises column operating pressure. This article presents several solutions for increasing compressor capacity through inexpensive process system modifications.

TEXT

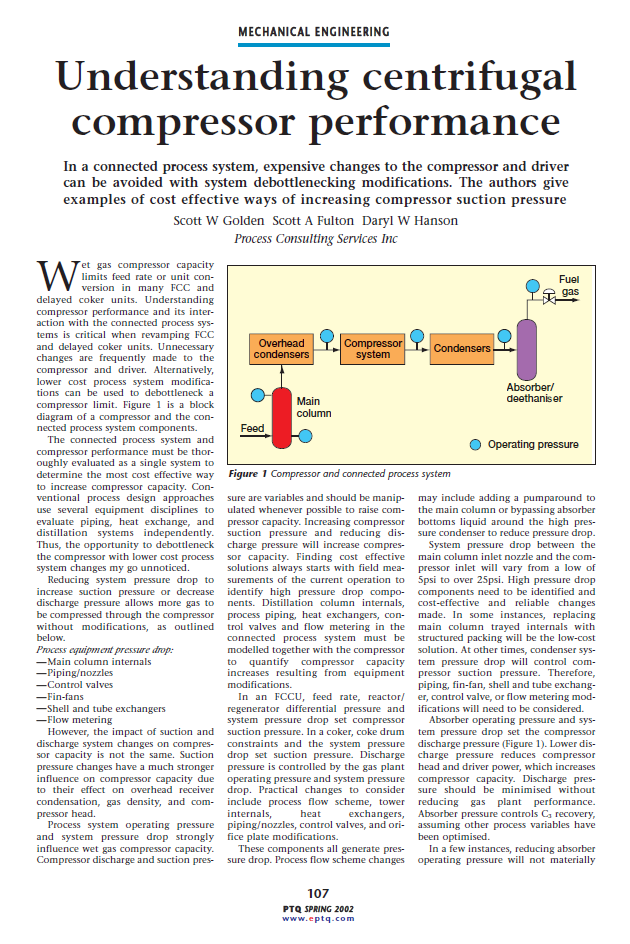

Wet gas compressor capacity limits feed rate or unit conversion in many FCC and delayed coker units. Understanding compressor performance and its interaction with the connected process systems is critical when revamping FCC and delayed coker units. Many times unnecessary changes are made to the compressor and driver. Alternatively, lower cost process system modifications can be used to debottleneck a compressor limit. Figure 1 shows a block diagram of a compressor and the connected process system components.

The connected process system and compressor performance must be thoroughly evaluated as a single system to determine the most cost-effective way to increase compressor capacity, but conventional process design approaches use several equipment disciplines to evaluate piping, heat exchange, and distillation systems independently. Thus the opportunity to debottleneck the compressor with lower cost process system changes may go unnoticed.

Reducing system pressure drop to increase suction pressure or decrease discharge pressure allows more gas to be compressed through the compressor without modifications. However, the impact of suction and discharge system...