Steam Reboiler System Operations

SUMMARY

Basic heat exchange principles are used to explain gas plant thermosiphon reboiler hydraulic constraints. Field measurements help clarify "off-design" operations that were not apparent and were causing high condensate levels.

TEXT

Process equipment performance is sometimes baffling. An FCC gas plant thermosiphon reboiler installed at CITGO Petroleum Corporation's Corpus Christi, Texas refinery showed symptoms that indicated hyrdaulic contraints. High condensate levels ocurred- the flow control valve went 100% open even though the steam flow rate was less than 15% of design. It appeared the exchanger would not meet its design duty due to condensate hydraulic limits.

Field mesaurements and further analysis using fundamental engineering principles showed high condensate levels were a result of inherent operating characteristics and not problems with design or operation. Further testing confirmed the exchanger met its design duty. Basic heat exchange principles will be used to explain the observed steam reboiler operations.

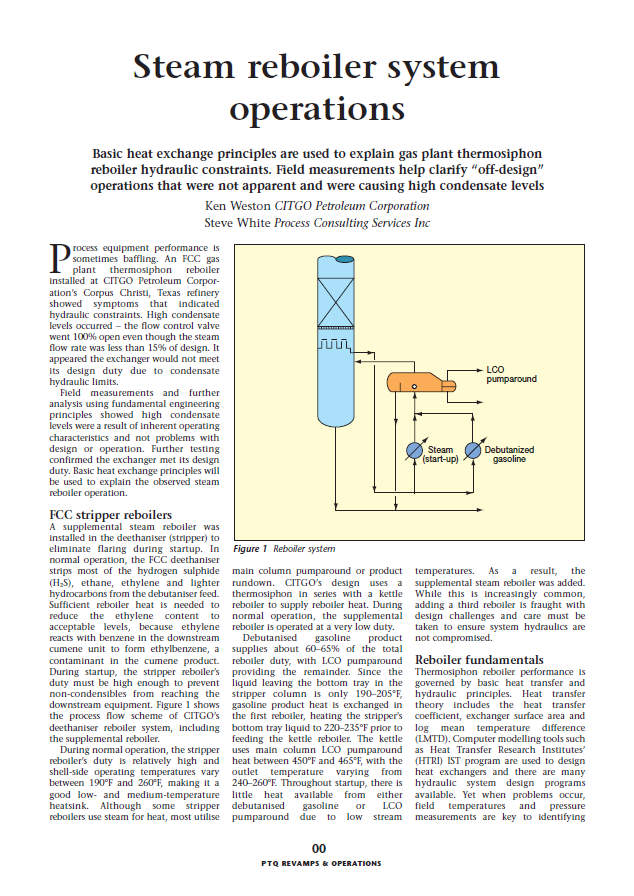

A supplemental steam reboiler was installed in the deethaniser (stripper) to eliminate flaring during startup. In normal operations, the FCC deethaniser strips most of the hydrogen sulphide...