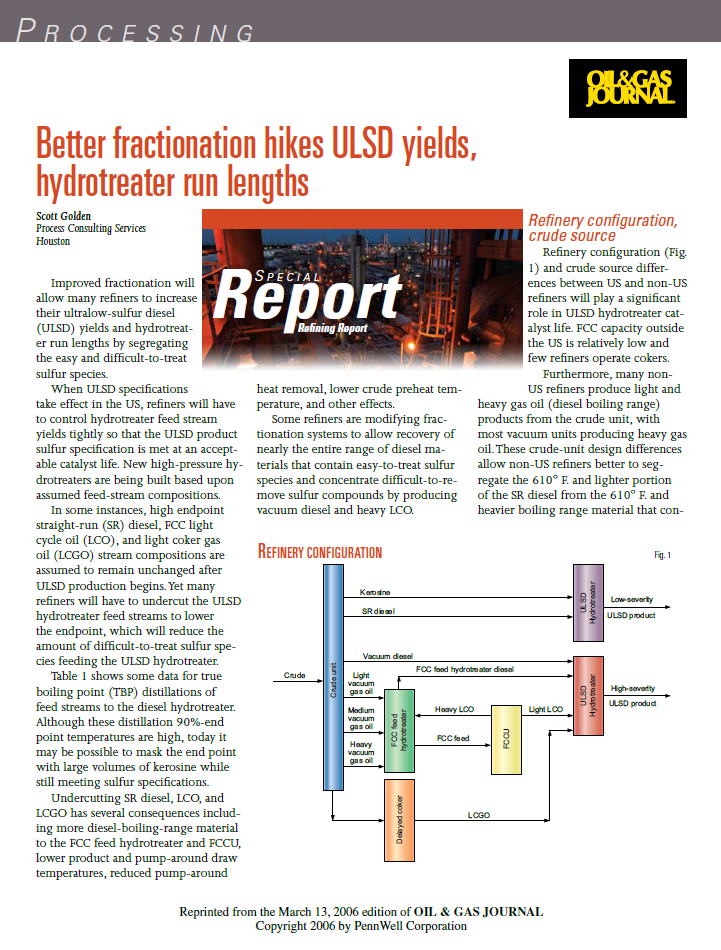

Improved CDU, FCC and Coker main column fractionation maximizes diesel boiling range yields while eliminating hard-to-treat sulfur components from the hydrotreater feed. Hydrotreater run lengths can be materially improved by improving the segregation of easy-to-treat and hard-to-treat sulfur species in upstream distillation units.

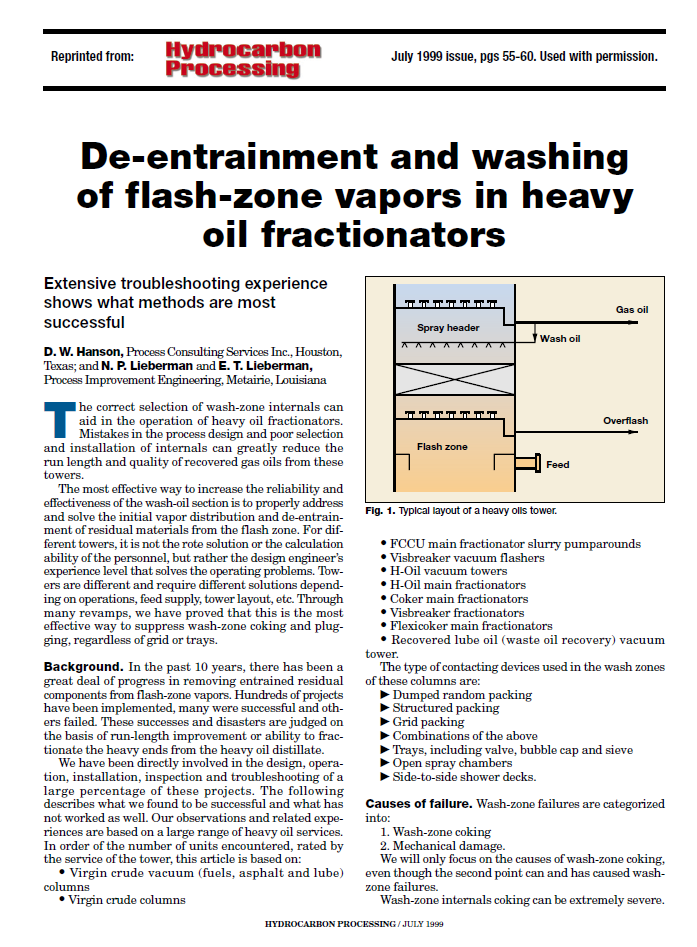

Read MoreExtensive troubleshooting experience shows what methods are most successful.

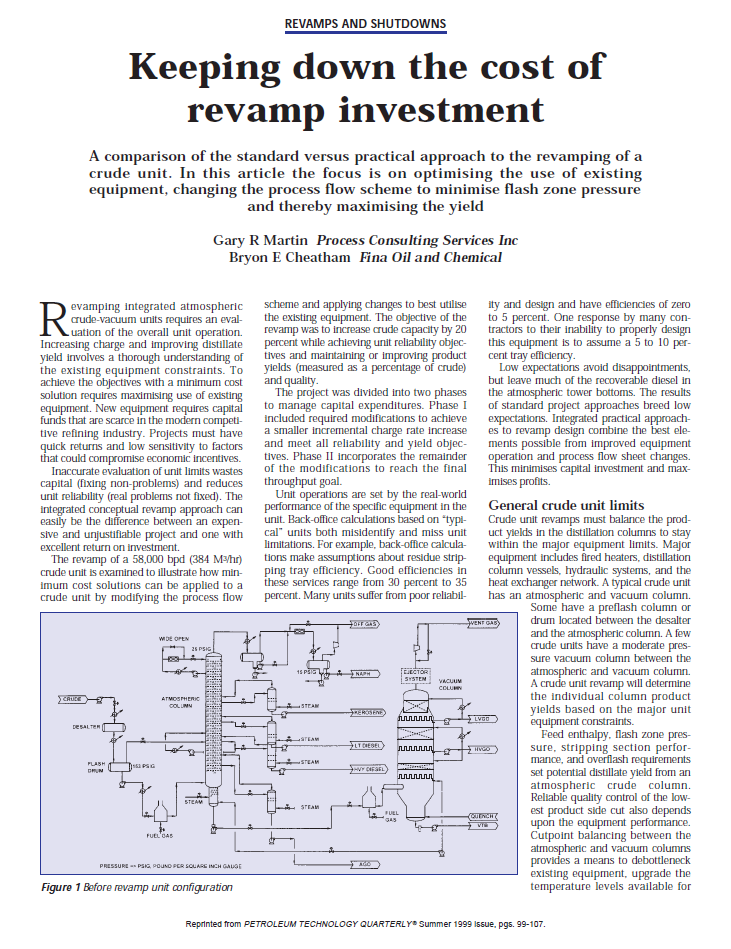

Read MoreA comparison of the standard versus practical approach to the revamping of a crude unit. In this article the focus is on optimising the use of existing equipment, changing the process flow scheme to minimise flash zone pressure and thereby maximising the yield.

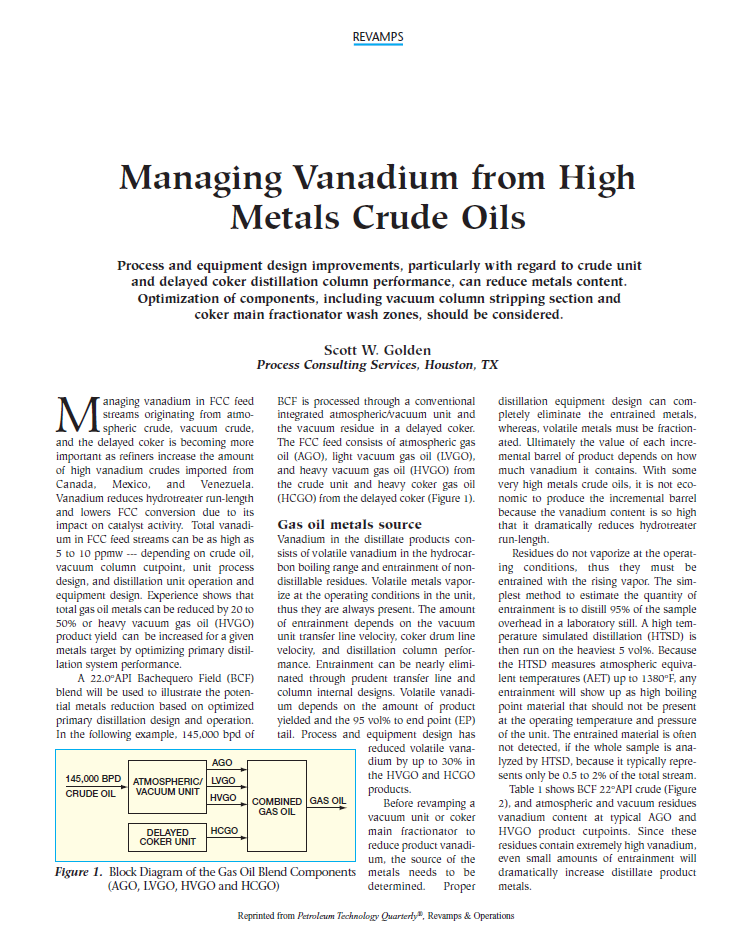

Read MoreProcess and equipment design improvements, particularly with regard to crude unit and delayed coker distillation column performance, can reduce metals content. Optimization of components, including vacuum column stripping section and coker main fractionator wash zones, should be considered.

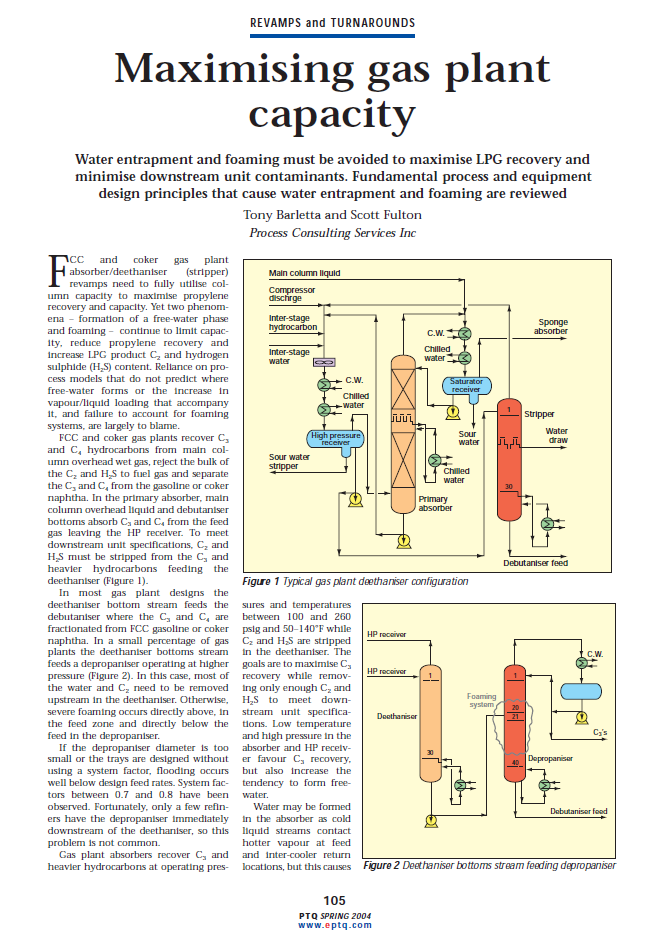

Read MoreWater entrapment and foaming must be avoided to maximize LPG recovery and minimize downstream unit contaminants. Fundamental process and equipment design principles that cause water entrapment and foaming are reviewed.

Read More