Extensive troubleshooting experience shows what methods are most successful.

Read MoreHeavy Canadian crudes pose serious challenges during the process of desalting due to their inherent properties. This article presents an overview of critical desalter design and operating considerations to overcome various operational issues.

Read MorePreheat train design for heavy Canadian crudes can be very challenging, requiring an approach not normally required with other crudes.

Read MoreNew units for processing heavy crudes should not be designed using conventional practices or run length with be short, and product yields and quality poor.

Read MoreWhen designing vacuum units for processing heavy Canadian crudes, reliability costs can be high if the feedstock’s thermal instability is not fully appreciate. Process design considerations affection VGO yield and quality are discussed.

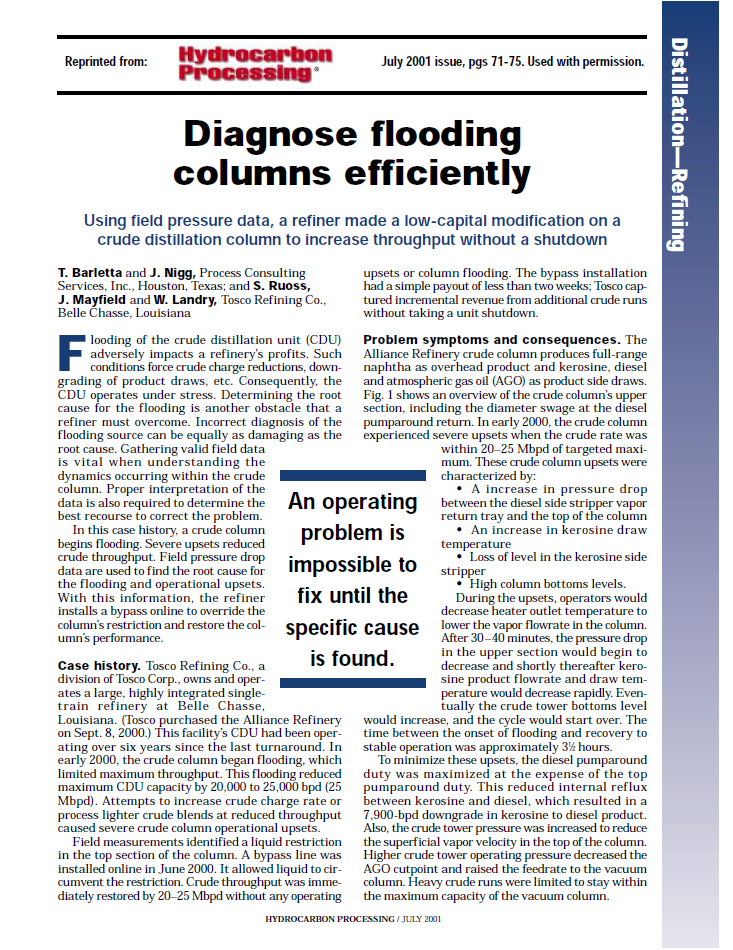

Read MoreUsing field pressure data, a refiner made a low-capital modification on a crude distillation column to increase throughput without a shutdown.

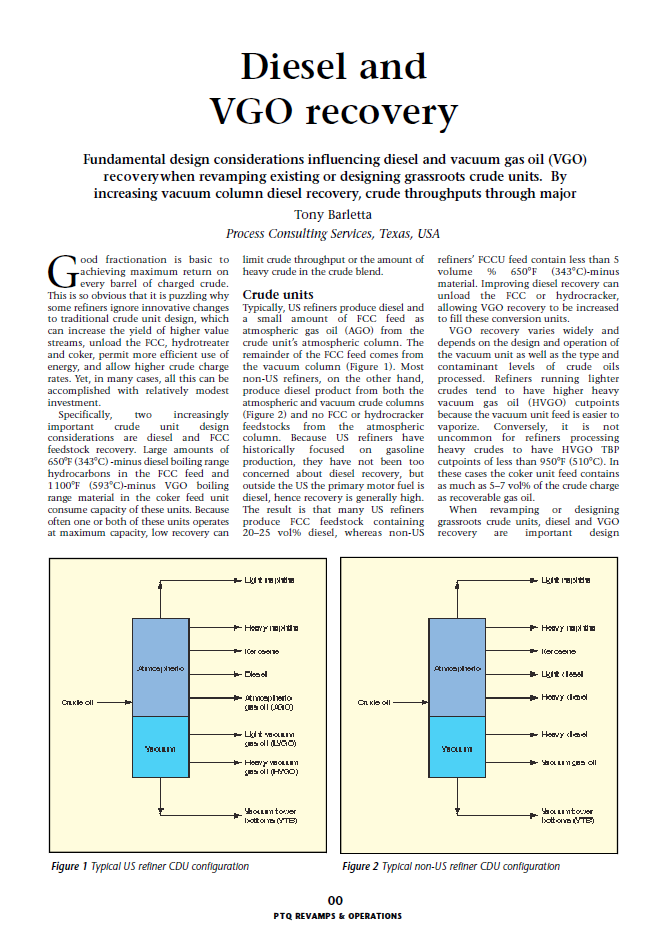

Read MoreFundamental design considerations influencing diesel and vacuum gas oil (VGO) recovery when revamping existing or designing grassroots crude units.

Read MoreUnit charge rate and reactor conversion were increased by elimination of stripper column flooding. Chemical-grade propylene specifications were met and C2 excursions in mixed C2/C3 streams were eliminated.

Read MoreStructured packing can influence unit pressure profiles and increase capacity.

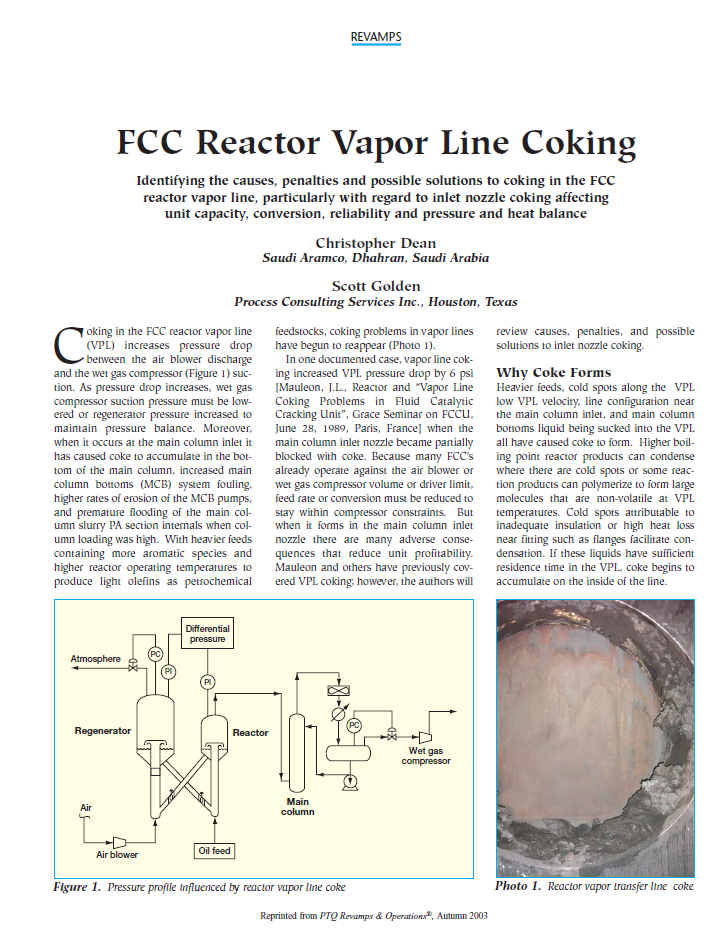

Read MoreIdentifying the causes, penalties and possible solutions to coking in the FCC reactor vapor line, particularly with regard to inlet nozzle coking affecting unit capacity, conversion, reliability and pressure and heat balance.

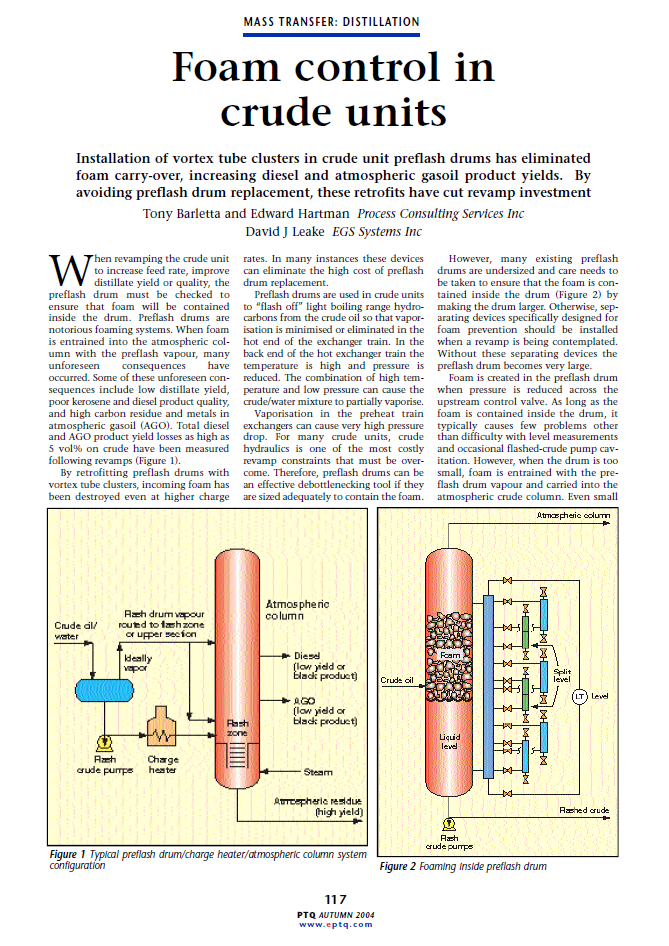

Read MoreInstallation of vortex tube clusters in crude unit preflash drums has eliminated foam carry-over, increasing diesel and atmospheric gasoil product yields. By avoiding preflash drum replacement, these retrofits have cut revamp investment.

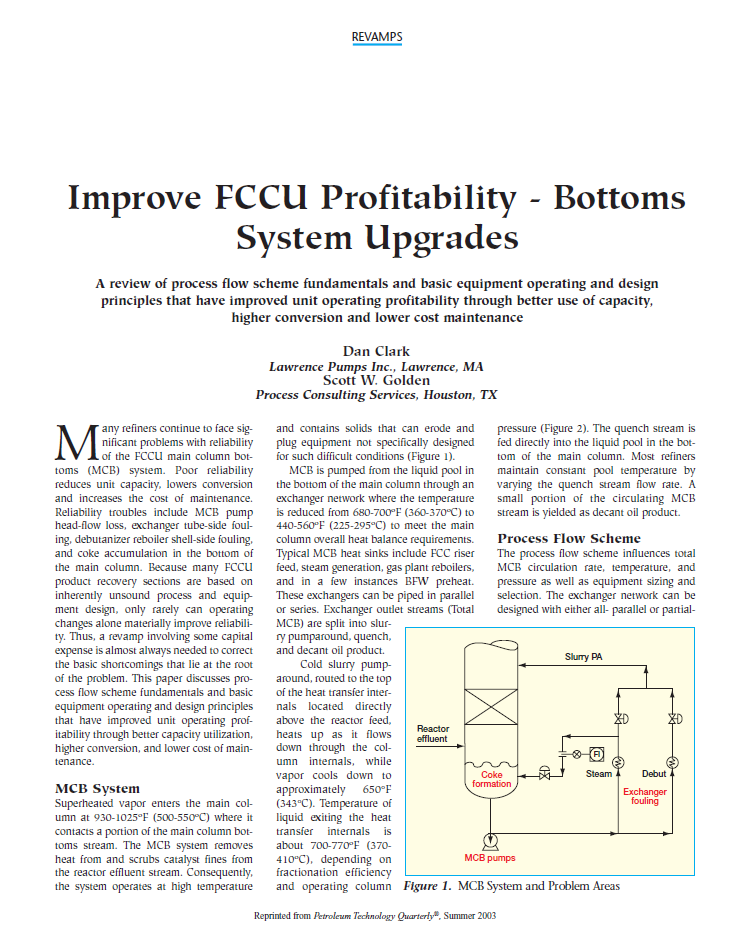

Read MoreA review of process flow scheme fundamentals and basic equipment operating and design principles that have improved unit operating profitability through better use of capacity, higher conversion and lower cost maintenance.

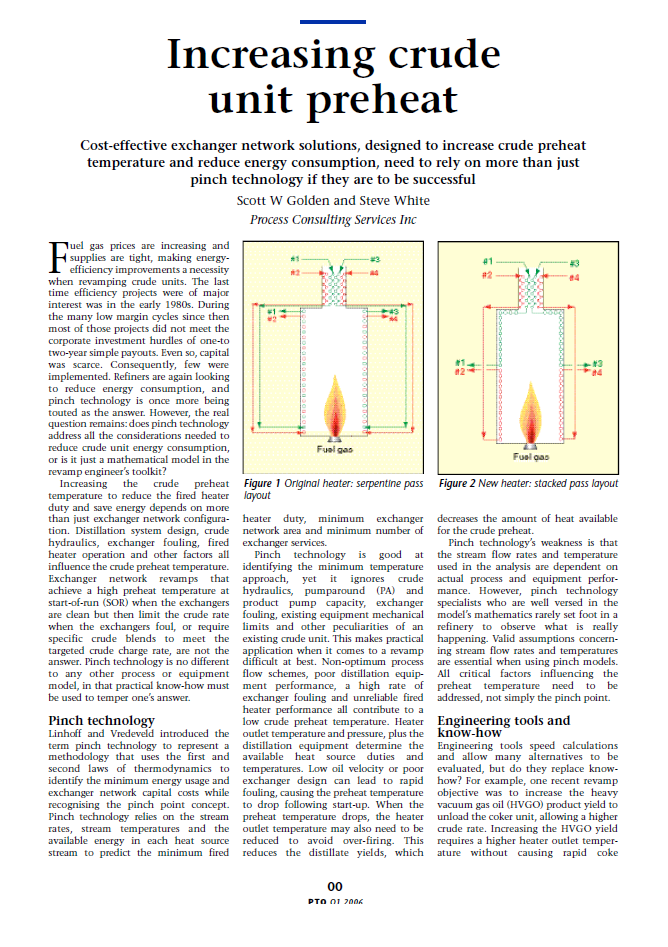

Read MoreCost-effective exchanger network solutions, designed to increase crude preheat temperature and reduce energy consumption, need to rely on more than just pinch technology if they are to be successful.

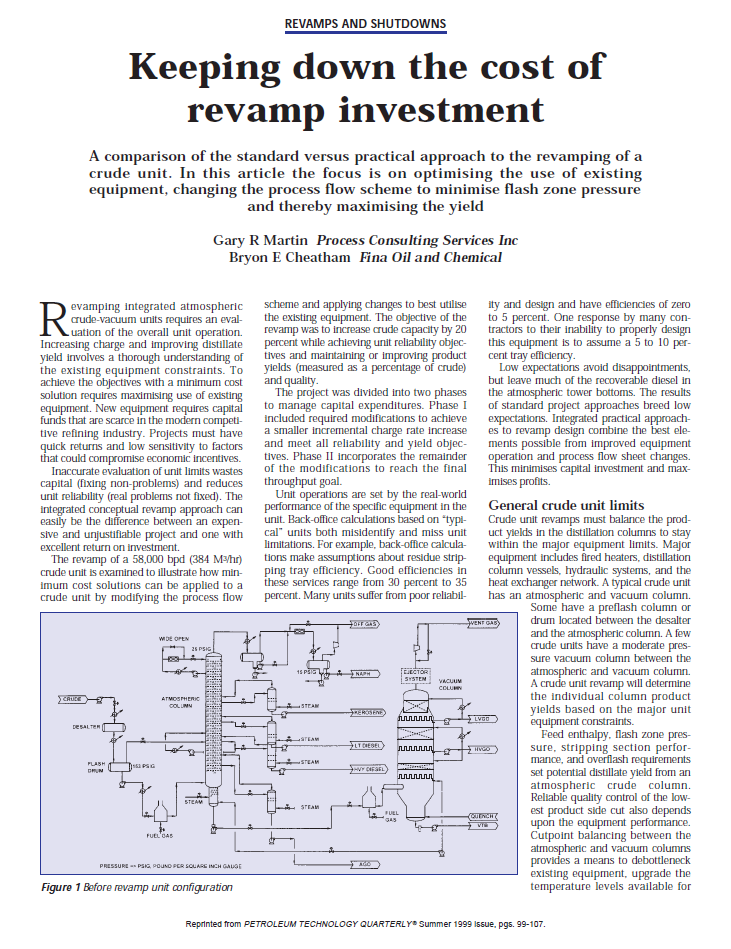

Read MoreA comparison of the standard versus practical approach to the revamping of a crude unit. In this article the focus is on optimising the use of existing equipment, changing the process flow scheme to minimise flash zone pressure and thereby maximising the yield.

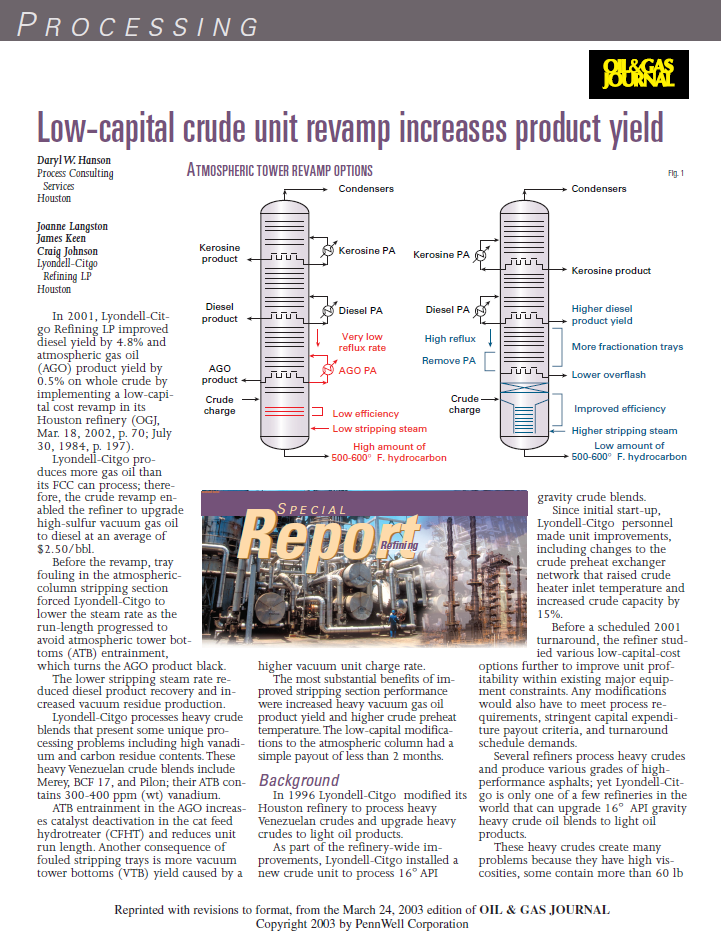

Read MoreCrude unit revamps can sometimes yield large economic improvements with low-capital investment. In this case study, improving atmospheric crude column stripping section efficiency improved diesel yields and unloaded the downstream vacuum column ejectors, increasing VGO yield. The low-capital modifications made in this revamp had a simple payout of less than 2 months.

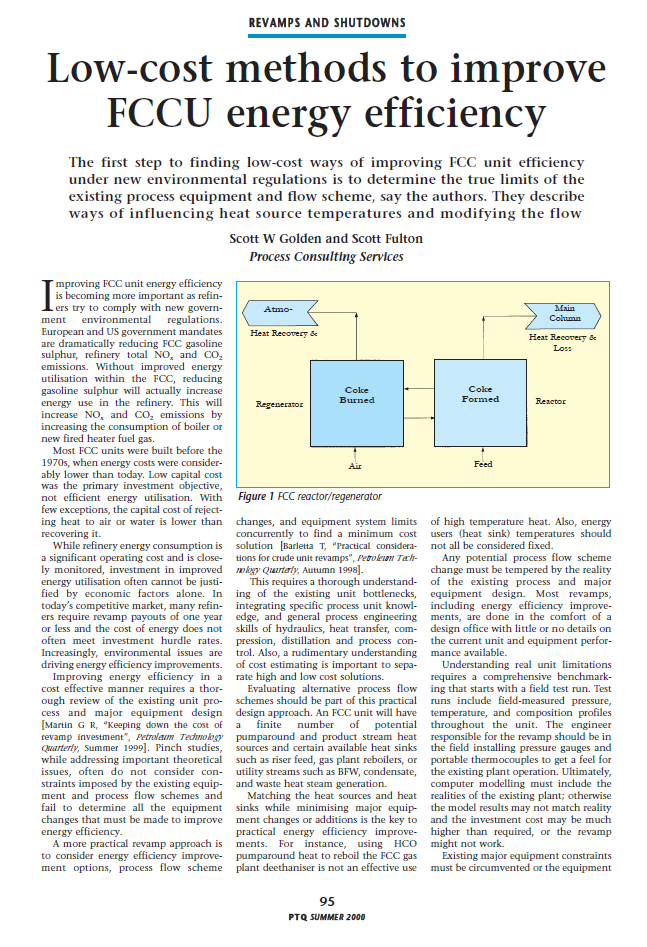

Read MoreThe first step to finding low-cost ways of improving FCC unit efficiency under new environmental regulations is to determine the true limits of the existing process equipment and flow scheme, say the authors. They describe ways of influencing heat source temperatures and modifying the flow.

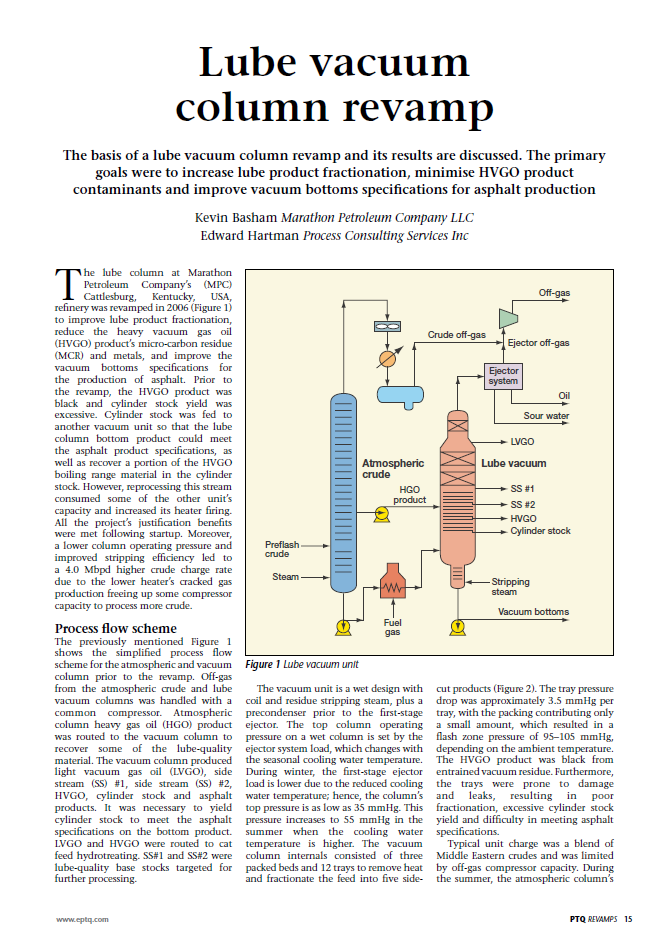

Read MoreThe basis of a lube vacuum column revamp and its results are discussed. The primary goals were to increase lube product fractionation, minimise HVGO product contaminants and improve vacuum bottoms specifications for asphalt production.

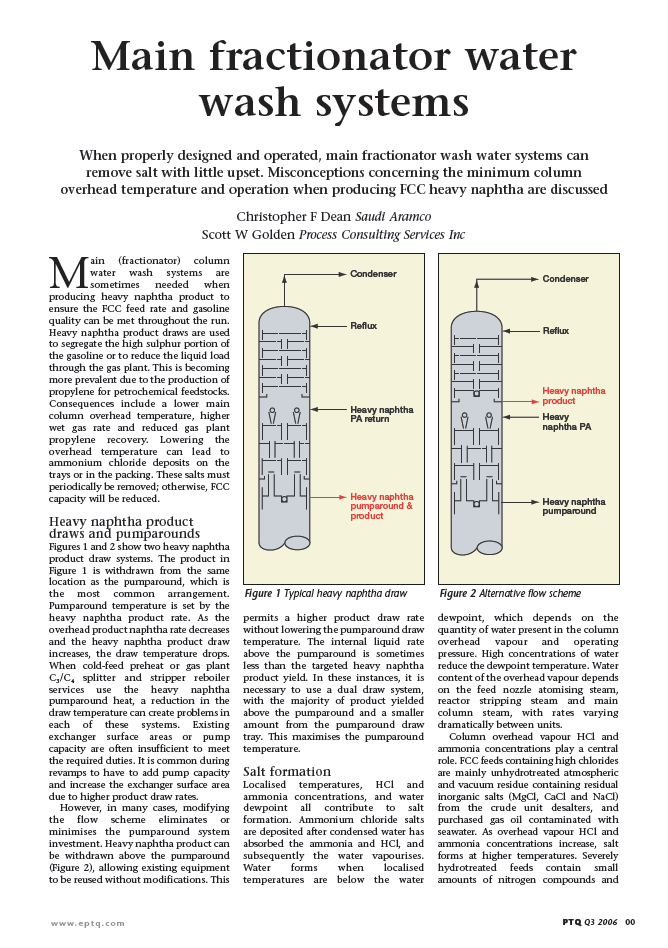

Read MoreWhen properly designer and operated, main fractionator wash water systems can remove salt with little upset. Misconceptions concerning the minimum column overhead temperature and operation when producing FCC heavy naphtha are discussed.

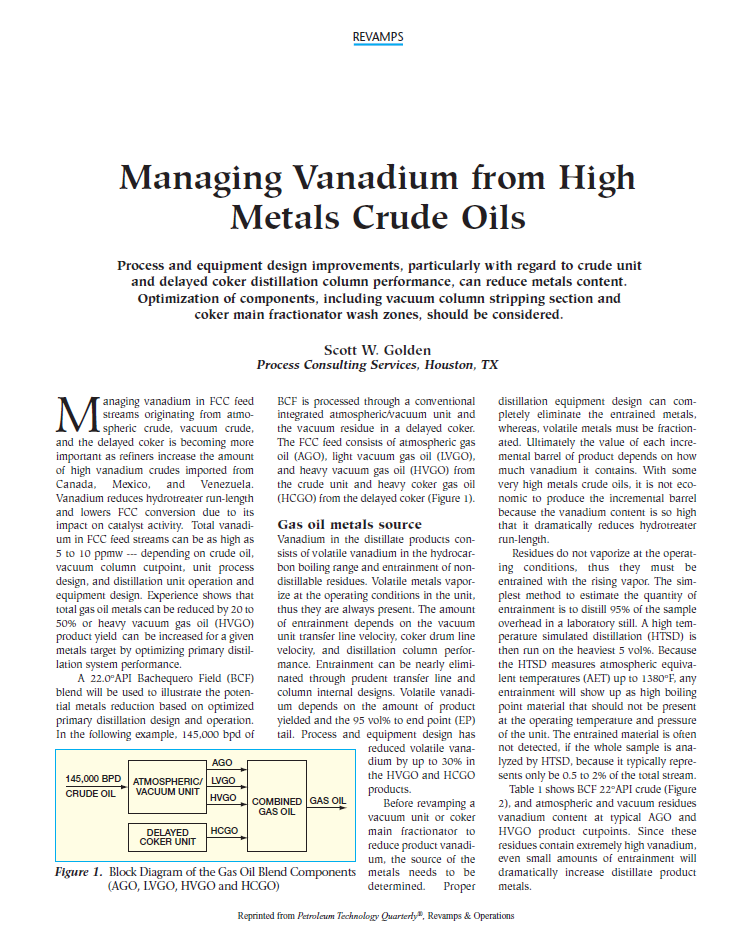

Read MoreProcess and equipment design improvements, particularly with regard to crude unit and delayed coker distillation column performance, can reduce metals content. Optimization of components, including vacuum column stripping section and coker main fractionator wash zones, should be considered.

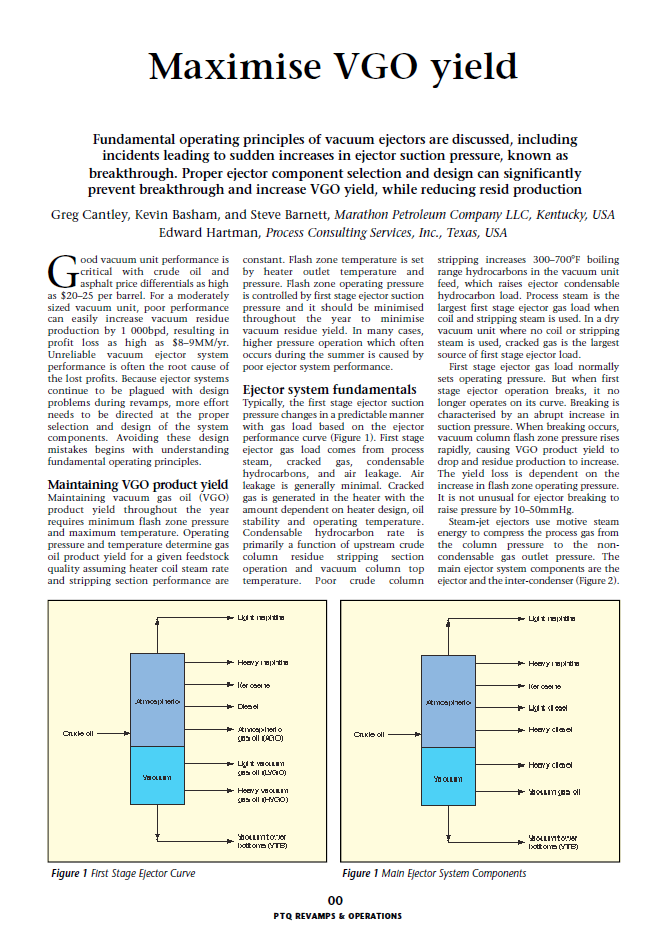

Read MoreFundamental operating principles of vacuum ejectors are discussed, including incidents leading to sudden increases in ejector suction pressure, known as breakthrough. Proper ejector component selection and design can significantly prevent breakthrough and increase VGO yield, while reducing resid production.

Read More