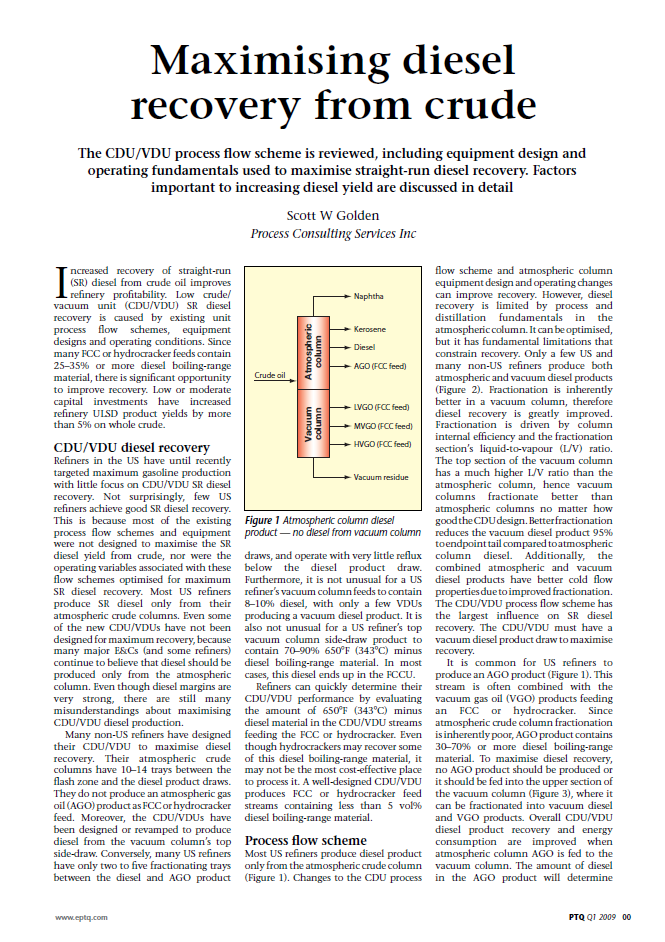

The CDU/VDU process flow scheme is reviewed, including equipment design and operating fundamentals used to maximise straight-run diesel recovery. Factors important to increasing diesel yield are discussed in detail.

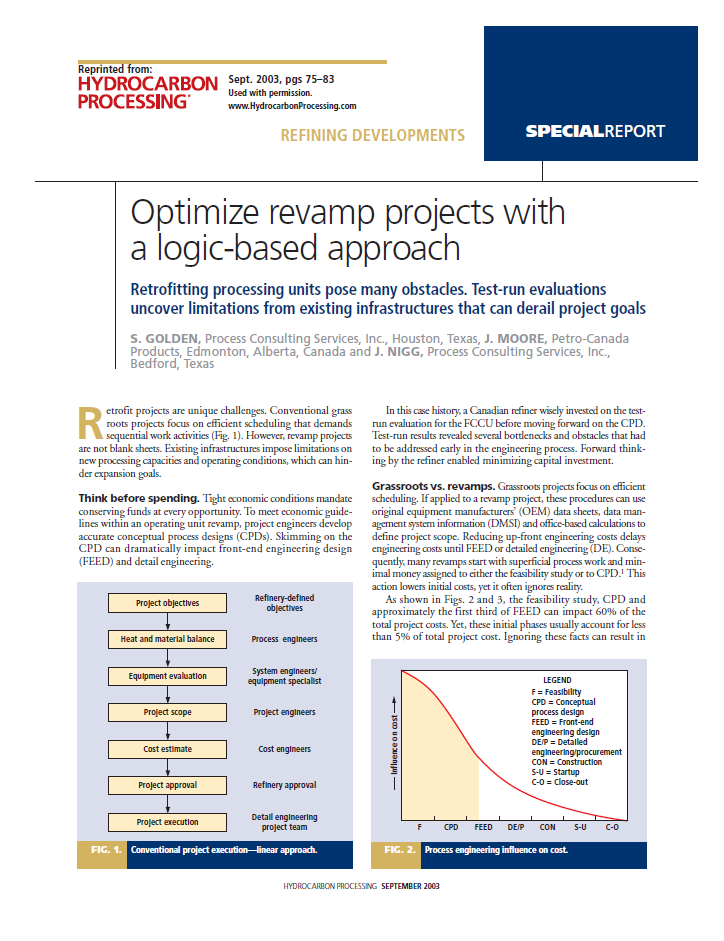

Read MoreRetrofitting processing units pose many obstacles. Test-run evaluations uncover limitations from existing infrastructures that can derail project goals.

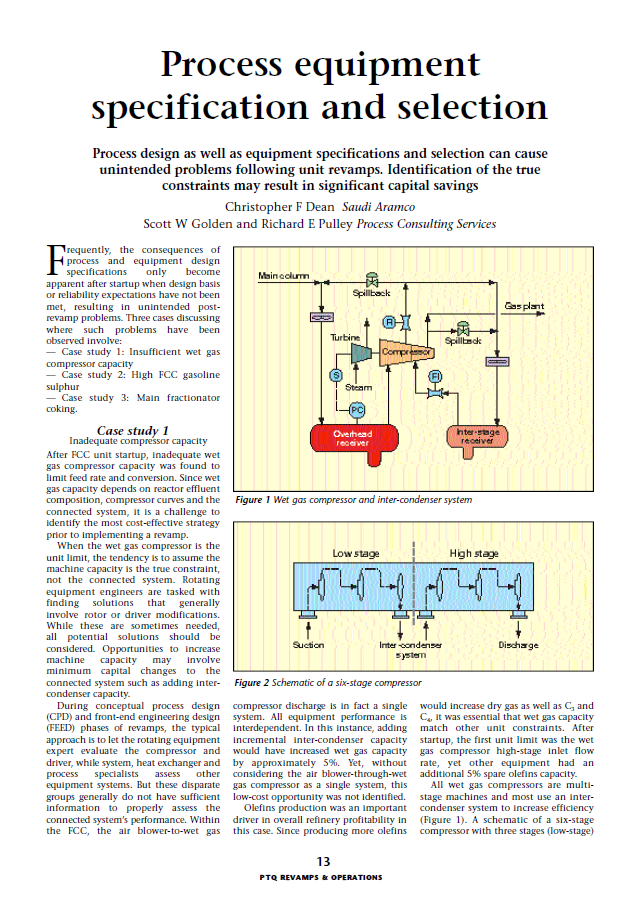

Read MoreProcess design as well as equipment specifications and selection can cause unintended problems following unit revamps. Identification of the true constraints may result in significant capital savings.

Read MoreA refiner producing various grades of asphalt from Boscan crude revamped their CDU to maximize asphalt yield while meeting product quality. These heavy crudes are difficult to process and specifications can be challenging when producing performance grade material. The successful revamp detailed in this article increased asphalt yield by 2% on whole crude and greatly improved unit stability.

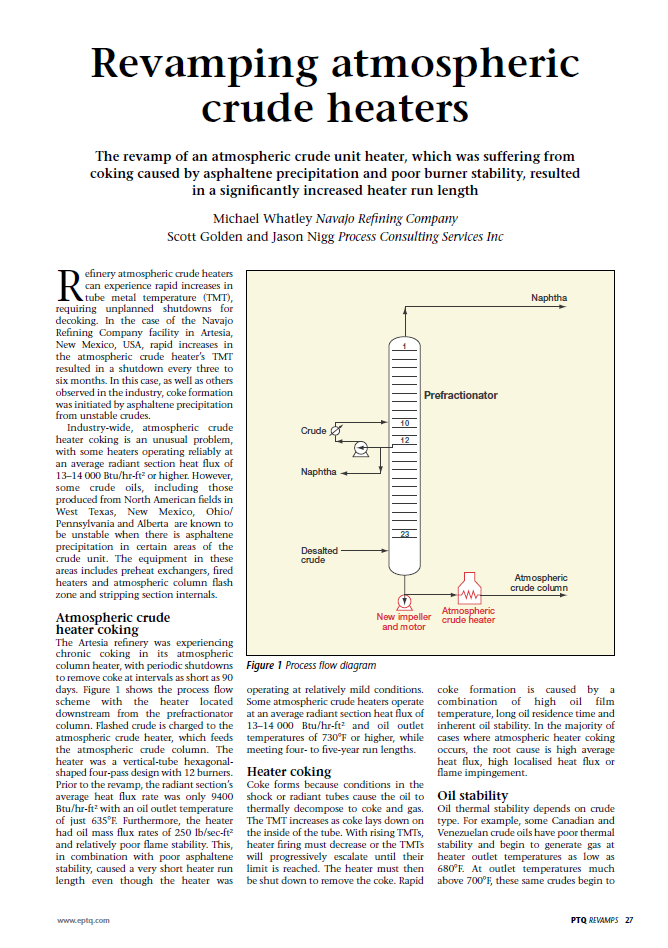

Read MoreThe revamp of an atmospheric crude unit heater, which was suffering from coking caused by asphaltene precipitation and poor burner stability, resulting in a significantly increased heater run length.

Read MoreWith desirability of getting the maximum use out of existing equipment when revamps are planned - not least to minimise investment costs - a rigorous approach to CPD is required to avoid scope growth.

Read MoreBy improving the operation of nonrotating equipment, a refiner minimizes losses and raises process profitability.

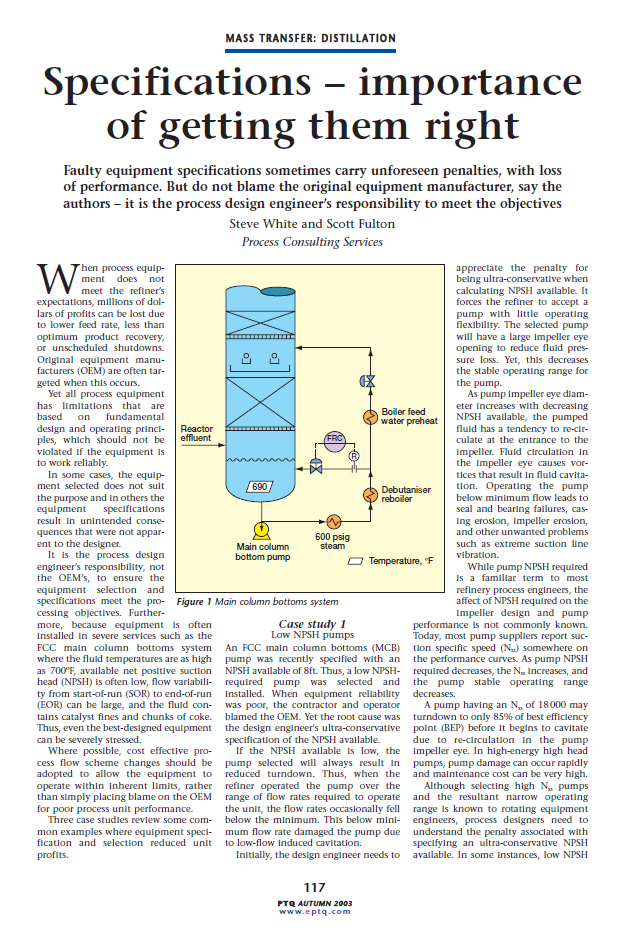

Read MoreFaulty equipment specifications sometimes carry unforeseen penalties, with loss of performance. But do not blame the original equipment manufacturer, say the authors- it is the process design engineer's responsibility to meet the objectives.

Read MoreBasic heat exchange principles are used to explain gas plant thermosiphon reboiler hydraulic constraints. Field measurements help clarify "off-design" operations that were not apparent and were causing high condensate levels.

Read More