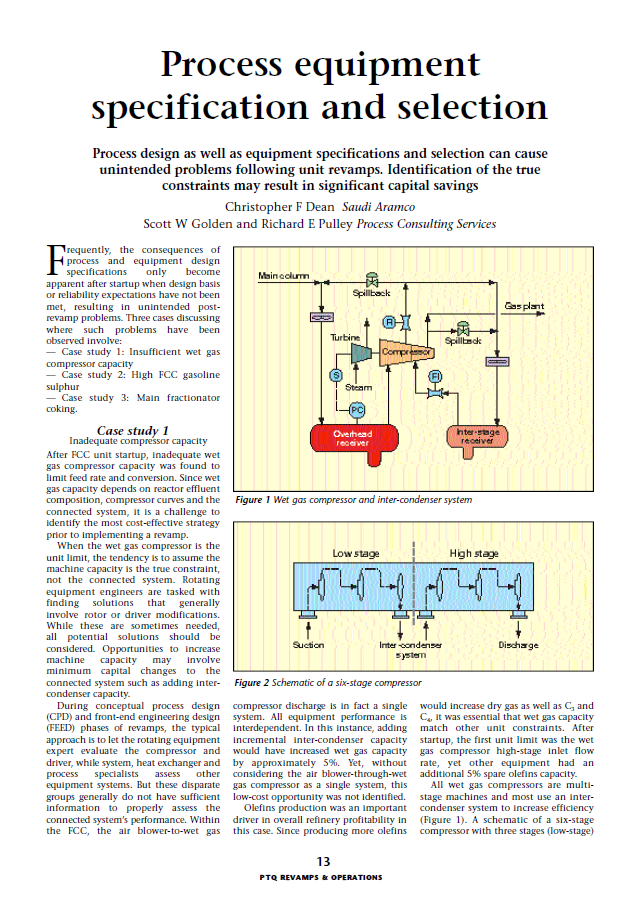

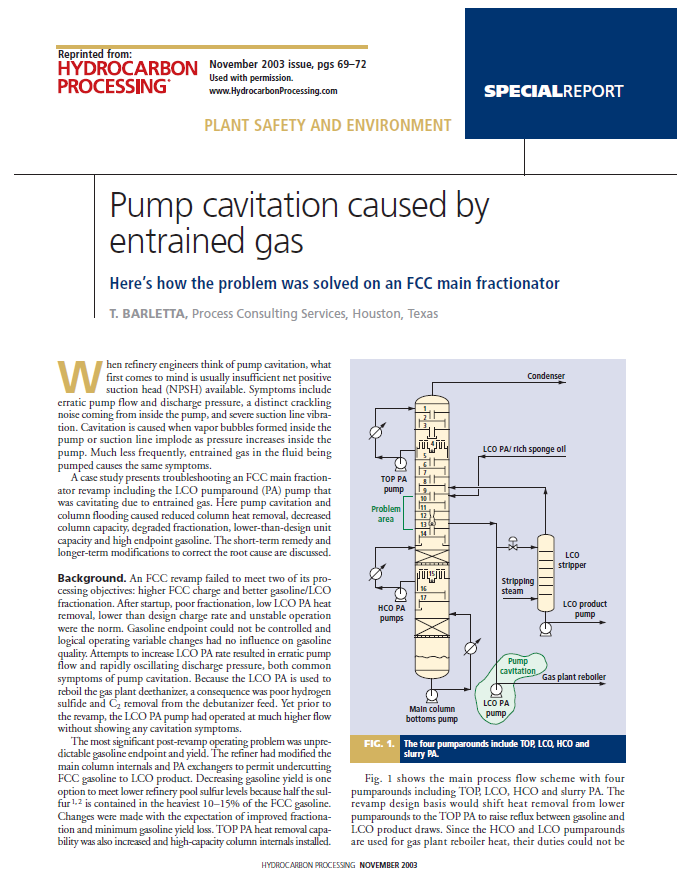

Process design as well as equipment specifications and selection can cause unintended problems following unit revamps. Identification of the true constraints may result in significant capital savings.

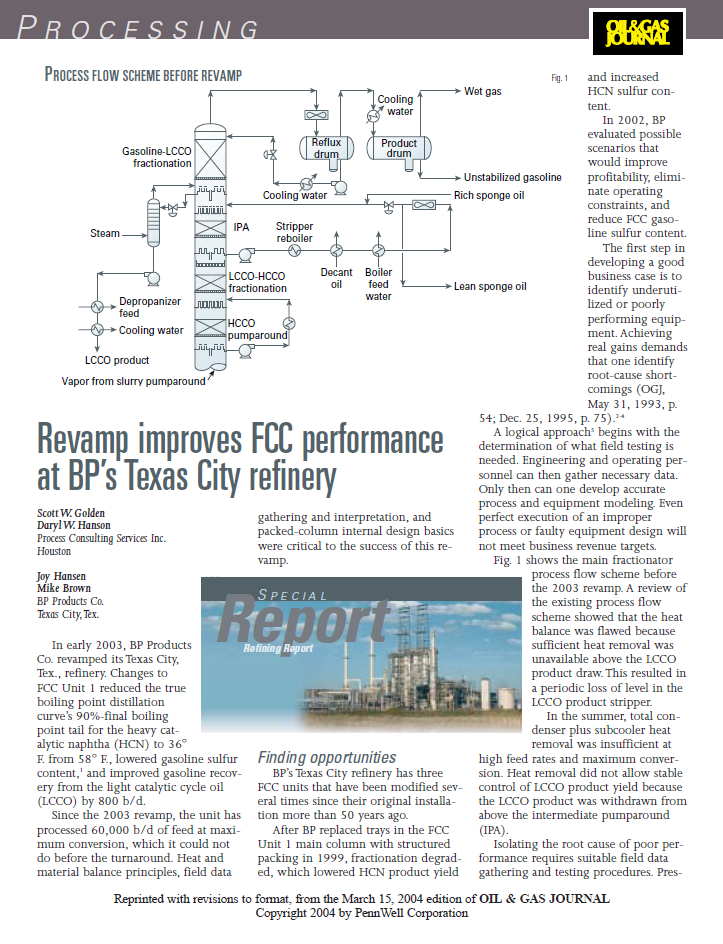

Read MoreHere’s how the problem was solved on an FCC main fractionator.

Read MoreBP Texas City revamped their No. 1 FCC main fractionator to improve fractionation, reduce pressure drop and lower naphtha sulfur content. Following the revamp the unit was able to increase capacity and operate at maximum conversion. Careful pre-engineering data gathering and the application of solid engineering fundamentals were critical to the success of this revamp.

Read MoreWith desirability of getting the maximum use out of existing equipment when revamps are planned - not least to minimise investment costs - a rigorous approach to CPD is required to avoid scope growth.

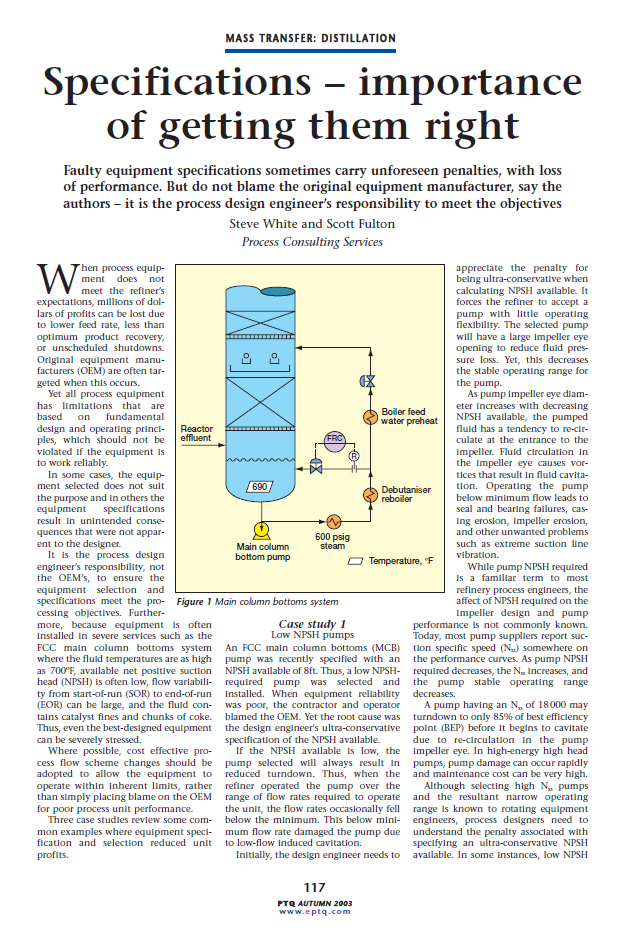

Read MoreFaulty equipment specifications sometimes carry unforeseen penalties, with loss of performance. But do not blame the original equipment manufacturer, say the authors- it is the process design engineer's responsibility to meet the objectives.

Read MoreBasic heat exchange principles are used to explain gas plant thermosiphon reboiler hydraulic constraints. Field measurements help clarify "off-design" operations that were not apparent and were causing high condensate levels.

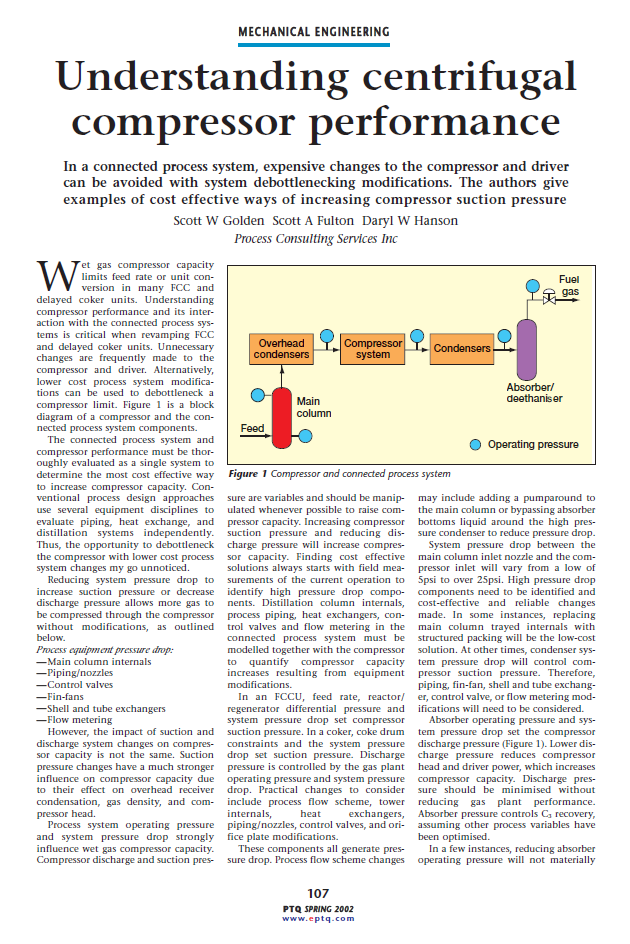

Read MoreUnderstanding how FCC and Delayed Coker wet gas compressor capacity is impacted by system pressure drop allows low cost changes to be made without expensive compressor modifications. In many instances high pressure drop caused by poor system design reduces unit capacity, lowers conversion, or raises column operating pressure. This article presents several solutions for increasing compressor capacity through inexpensive process system modifications.

Read MoreFCC pressure balance is one of the key operating parameters that set catalyst circulation, unit charge rate, and conversion. Quantifying the individual system component pressure drops and the relative cost of reducing them allows cost-effective revamps to be implemented. Several examples present the benefits from actual revamps, which have increased unit capacity by 12%-40%.

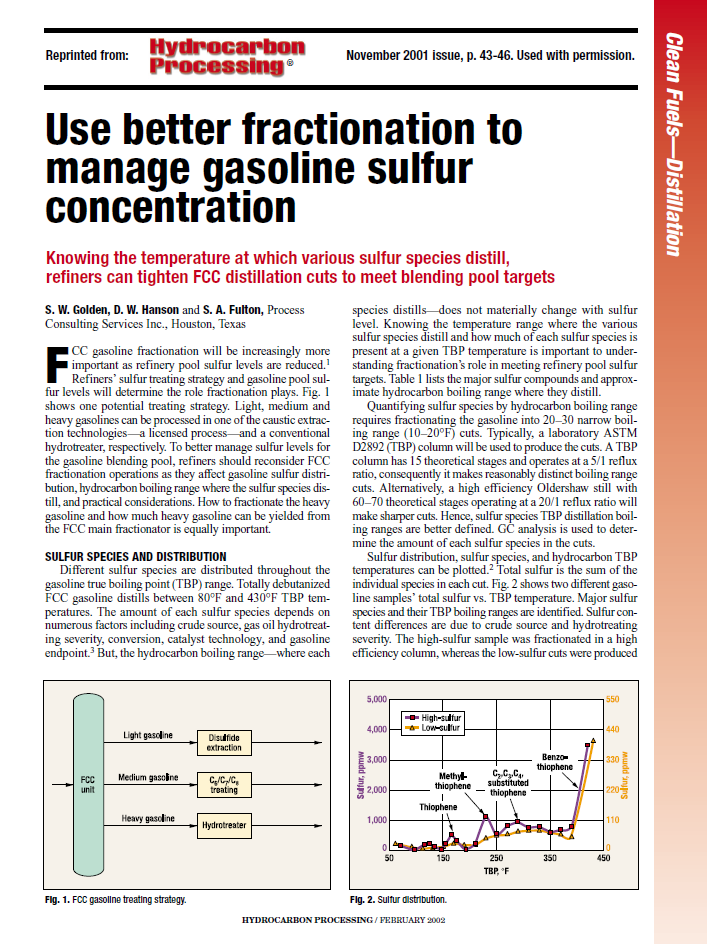

Read MoreKnowing the temperature at which various sulfur species distill, refiners can tighten FCC distillation cuts to meet blending pool targets.

Read More